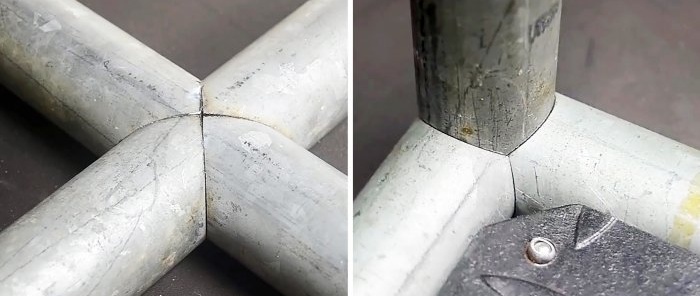

When laying metal pipelines and welding metal structures, complex connections must be made. Situations of welding three profiles in different planes are common, for example, when creating shelving. When installing heating systems, cross-connections of pipes occur - when four profiles are joined at right angles in one plane. An overlapping connection disrupts the geometry and worsens the appearance of the product. Knowing a couple of secrets, you can cook reliable structures with an aesthetic appearance.

What you will need

In addition to the parts to be welded, you need:- several sheets of paper;

- pencil;

- ruler and caliper;

- an angle grinder (grinder) with an abrasive wheel for cutting steel;

- metal cutting machine with a vice;

- individual protection means;

- file or needle file;

- paper scissors;

- construction square.

To connect three or four parts in different planes, they need to be prepared.

Connection of four pipes of the same diameter

The pipe is wrapped in paper. The last one marks the place where the ends of the leaf meet - its length is equal to the length of the pipe.

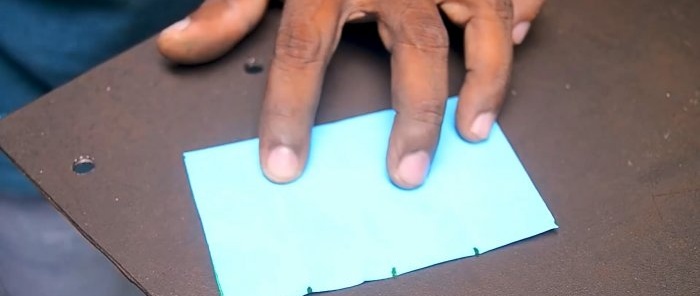

The excess part of the paper is cut off. Next, it is folded in half along its length. A marking line is drawn in the middle in the width direction.

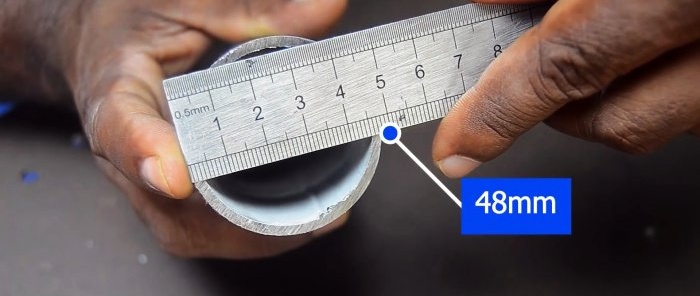

A ruler or caliper (more precisely) measures the outer diameter of the pipe.

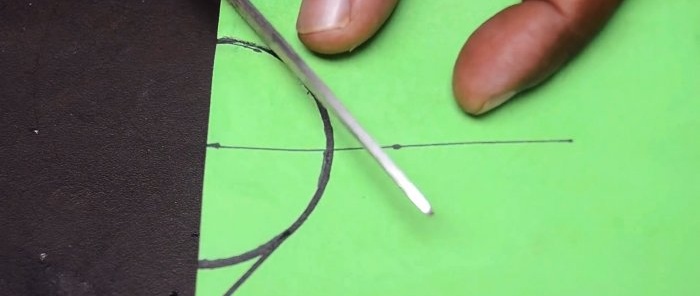

Two marks are placed on both sides of the line at a distance from the radius of the pipe. The radius of the pipe is also plotted on the center line. It (or the scrap) is placed between three marks and outlined.

Tangents to the semicircle are drawn from both corners of the sheet. The unnecessary part of the paper is cut out along them.

Each of the four pipes is wrapped in a leaf, and the markings are transferred to them.

Unnecessary parts are cut off with a grinder, and the joints are finished with a file or needle file.

The structure is ready for welding.

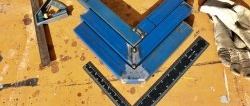

Connecting three corners in different planes

To join three corners, for example, when welding shelves, racks, drawers, their sides must be cut correctly.

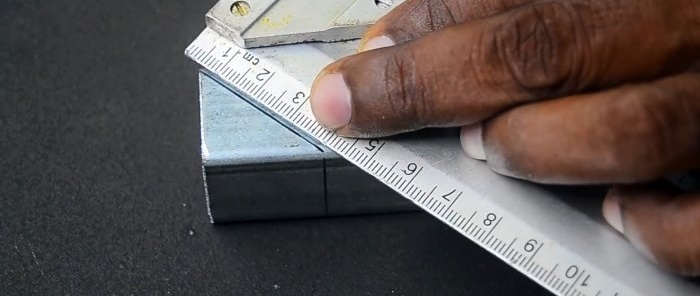

Using a square set at 45 degrees, marks are drawn from the stiffener on both sides to the edges of the profile.

Three corners are cut off with an angle grinder, and the joints are processed with a file.

The structure is ready.

Connection of three “squares”

The method is similar to joining angles, adjusted for the geometry of rolled metal. A diagonal is laid on one side of the profile, starting from the upper left corner. On the next one (clockwise) there is a perpendicular to the length of the profile, which begins at the end of the diagonal.

It continues on the next side.

On the last plane a diagonal is laid, which begins at the end of the perpendicular.

Preparations are complete.

Connection of three pipes in different planes

Similar to the first case, the pipe is wrapped in paper, and the latter is cut to the same length as the circumference. The leaf is folded twice in length, then a second time.

The paper is unfolded and the places of bends are marked on it.

The pipe is again wrapped in a sheet. Marks are transferred to it and connected by a line.

A mark is placed on the vice at the height of the pipe radius.

The first mark on the pipe is aligned with the mark on the vice.

The workpiece is cut on the machine at an angle of 45 degrees.

The pipe is turned counterclockwise to the second mark and again cut at 45 degrees. The profiles are connected.

With precise marking, the gaps are minimal.

When working with an angle grinder and a profile cutting machine, you should follow safety precautions: use glasses and headphones. Do not rush to process the workpieces immediately after trimming - they are hot. It is recommended to wear gloves, as the metal edges are sharp.