Sometimes you need to fasten steel cables to a wall or ceiling, but there are no special fasteners at hand. For a home craftsman, this is not a problem; using available materials and ingenuity, the cables are easily attached exactly where necessary.

Tools you will need for the job

To make homemade fasteners, you will need tools and materials:- vice;

- drilling machine;

- welding machine;

- perforator;

- pliers;

- open-end or ring wrenches;

- Bulgarian;

- hammer;

- steel cables;

- screws and nuts of different designs;

- dowels;

- thick flexible wire.

First idea: how to attach a cable to a wall at a right angle

Using a drilling machine and a vice, a through hole is made in the bolt along its entire length.

Without removing the finished bolt from the vice, a nut is screwed onto it, to which a piece of a long bolt without a head is welded.

The weld is cleaned with a grinder, a piece of the bolt with a nut is unscrewed and put aside for now.

A blank with a welded nut is driven into the wall with a hammer, where a hole is prepared with a hammer drill and a dowel is inserted, a bolt with a through hole is screwed into the nut.

A steel cable is inserted into the hole, the tip is removed from the cap, and secured by wrapping it with wire.

To keep the wire tightly, you do not need to wrap it, but twist the cable with pliers.

The cable can be easily tensioned by rotating the bolt.

Second idea: how to easily attach a cable to the wall

A hole is drilled in the cap nut, clamped in a vice.

An extension nut is welded to the workpiece with a hole, and the seams are cleaned with a grinder.

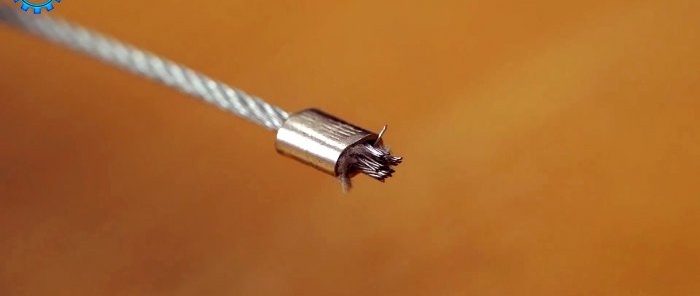

The cable is threaded, the tip is crimped with a suitable piece of tube using pliers.

A piece of a bolt without a head (one thread) is screwed into the prepared hole in the wall.

A blank of nuts with a cable is screwed onto the thread.

Third idea: how to connect 2 cables (reliable and removable connection)

A small piece of threaded bolt is prepared and the required amount is cut off. A hole is drilled into the workpiece to its full length using a drilling machine.

Make a slot in a piece of bolt in the middle on one side - the cables will go there.

Nuts are screwed onto the workpiece on both sides; it should not cover the sawn hole. Then the ends of two cables are inserted from the ends of the bolt and come out through a sawn hole in the middle.

All that remains is to bring the nuts together and tighten them with an open-end wrench - the cables are securely fastened!

Fourth idea: fastening the cable in the frame of a steel structure

The bolt is secured in a vice, and part of the thread is cut off with a grinder. A through hole is made in the workpiece using a drilling machine.

A cap nut is screwed onto the prepared bolt, and a hole is also made in it.

The nut is unscrewed, the bolt is inserted on one side of the iron blank, and the prepared cap nut is put on and tightened on the other side.

A steel cable is threaded into the hole in the blanks, the end is crimped with a piece of tube using pliers - ready!