To smoothly bend profile pipes at 90 degrees, some experience and separate calculations for each size are required. But any adult can handle this task if they have a special marking tool that can be adjusted to any size. It’s not difficult to make, and from waste materials.

Will need

Materials:- remainder of the steel sheet;

- a piece of steel strip;

- pieces of plexiglass;

- screw, washer and spring;

- spray paint.

The process of manufacturing a tool for marking a smooth 90-degree bend of profile pipes

The profile pipe is marked for a smooth 90-degree bend using a corresponding circle with diameters marked at right angles. The method is simple, but imprecise, and each pipe size requires its own circle. We will make a universal device, suitable for different sizes of pipes, easy to use and more accurate. From a steel sheet 3 mm thick, cut out a rectangle 75 × 90 mm.

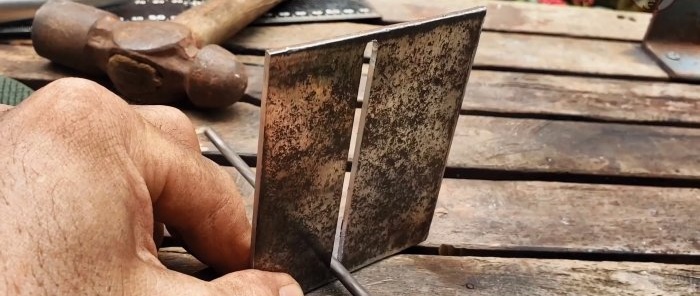

From a 5 mm thick strip we cut a piece 175×20 mm. Using a magnetic clamp, we weld the strip on edge along the short side of the rectangular plate. We grind the weld seams with a grinder.

At the free end of the strip from the plate side, drill a blind hole, cut a thread and screw in a screw.

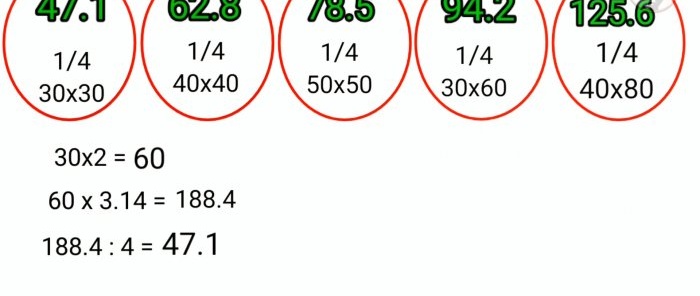

On the edge of the strip from the screw to the rectangular plate we make marks at a distance determined by the ratio: π×R/2, where π=3.14, R is the standard size of the profile pipe. So, for a square pipe 30×30 mm it is equal to 3.14×15=47.1 mm, 40×40 mm – 62.8 mm, 50×50 mm – 3.14×25=78.5 mm, 60× 60 mm – 3.14×30=94.2 mm, 40×80 mm – 3.14×40=125.6 mm, etc.

From the two marks furthest from the screw, we draw vertical lines along the surface of the plate to its free edge. At the ends of the most distant line we compare the holes, along the second line we align the vertical edge of the plate.

We connect the holes in the plate with a slot of width equal to the diameter of the holes. We process it with a round file to remove burrs and round the edges.

We deepen the marks on the strip with a file. We draw a line on the plate parallel to the slot and make marks vertically at a distance from the strip R/2, where R is the side of the profile pipe. For a pipe 30x30 mm it will be equal to: 30/2=15 mm, 40x40 mm - 20 mm, 50x50 mm - 25 mm, 60x60 mm - 30 mm, 40x80 mm - 40 mm, etc. d. Drill holes along these marks.

We cut out a plate 95×15×5 mm from plexiglass.

We draw a longitudinal central line on it and, from the starting point at the end of the plate, use a compass to mark the intersections with it, respectively, of radii equal to 32, 42, 52, 62 and 82 mm.

We drill holes at these points, including the common point. We grind the plexiglass plate and round the corners with sandpaper. We remove marks and particles from the plate with a solvent.

We paint the marking metal with spray paint and after drying, screw the plexiglass plate to the threaded hole on the steel strip with a spring-loaded screw.

Using the tool

The tool is easy to use. We measure the side of the profile pipe and draw a transverse line at the bend, install a plexiglass plate on it, moving the strip with marks along the adjacent side of the profile pipe.

Insert a marker into the corresponding hole in the plexiglass plate and draw a circular arc along the surface of the pipe. Depending on the standard size of the pipe, using the corresponding mark on the strip or plate, draw a vertical line along the surface of the pipe.

We transfer the marks to other sides and mark the places to be removed. After which the pipe easily and smoothly bends 90 degrees. All that remains is to fix the bend by welding.

If we measure the distance between the extreme vertical lines after marking, then they will be respectively equal for a pipe 30x30 mm - 47.1 mm, 40x40 mm - 62.8 mm, 50x50 mm - 78.5 mm, 60x 60 mm – 94.2 mm and 40×80 mm – 125.6 mm.

The value of R/2, which is needed for marking, can be easily found by pressing the strip with marks to the side of the profile pipe and using a marker through the corresponding hole in the metal plate to apply a mark to the surface of the pipe.