Kitchen blenders have a common problem - their knives, buttons or body break. As a result, when the engine is running, the device turns into a useless pile of garbage. If the blender can no longer be used for its main purpose, then you can use it as a motor donor for assembling a homemade milling cutter.

Materials:

- Old blender with running motor;

- sewer pipe 110 mm;

- drill chuck;

- plywood 10 mm;

- switch;

- M6 bolt with wing nut.

Any discs for angle grinders on AliExpress with a discount - http://alii.pub/61bjly

The process of making a router from a blender

It is necessary to disassemble the blender and remove the motor. Its part of the plastic body is cut off.

It will require a diffuser that directs the flow of air for cooling.

From a piece of plastic sewer pipe you need to make a motor housing that can be placed in a diffuser.

To do this, a strip is removed from the tube lengthwise to narrow it. If necessary, you can also trim the metal engine mount. It must fit into the body.

The narrowed body tube is glued together from the inside with an insert. The engine is placed in it and glued with a mount.

Then you need to attach a drill chuck to the side of the motor shaft that is free from the impeller. Since the diameters do not match, you can put a tube sleeve on it.

After this, you need to mount the router from a section of sewer pipe like a clamp. To do this, the pipe unfolds lengthwise, heats up, and its edges bend outward.

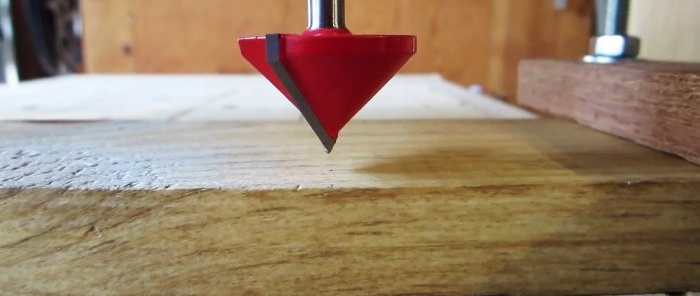

The result is a device that operates like a clamp. On one side, a plywood base with a hole for a cutter is glued into it. To increase rigidity, you will need to glue a round plywood insert inside. This is to increase the contact area between parts.

The standard engine diffuser is screwed onto a homemade housing. Then, to increase rigidity, you need to make and glue wooden pads onto the fastening jaws. Their presence will allow you to drill it and tighten it with a bolt without deforming the plastic.

A switch is embedded in the diffuser of the router. Then you need to cut a window in the casing above the sole to access the cartridge.

After this, the parts can be painted.

The result is an engine in a plastic case with good ventilation. The power button is located at the top in a convenient place. The engine is clamped into a casing with a sole, which, thanks to the wing nut, allows you to quickly adjust the reach of the cutter. The side window will provide access to the chuck to change accessories. Since the motors in blenders are powerful, such a device mills no worse than a commercial router. It may be less convenient due to its size, but you can quickly get used to it.