To sharpen metal drills correctly and quickly, you need a lot of experience and a steady hand. But by making a very simple jig from two pieces of wood and caps from plastic bottles, you can simplify this difficult and important operation to such a level that even a person who has never sharpened drills can handle it.

Will need

Materials and tools:

- dull metal drill;

- pieces of wooden boards or timber;

- two plastic bottles;

- hot glue;

- construction knife;

- gas-burner;

- sharpening machine (emery), etc.

High-quality and durable drills on AliExpress at a discount - http://alii.pub/5zwmxz

The process of making a jig and sharpening a drill using it

We cut a blank from a wooden board or timber in the form of a flat wedge with one angle of 90 degrees, 5 cm high and 8 cm long. Then the inclined plane of the wedge will make an angle of 116 degrees with the horizontal surface, and the sharpening of the drill will also have the same value.If a different sharpening angle is required, then it is necessary to change the angle of the wedge or the ratio of its height and length.

Cut off the necks with caps from two plastic bottles. Carefully trim the bottom of the necks so that they are flush with the lids.

Then we glue the necks with screwed caps together with hot glue.

Using a gas torch, we heat the cutting side of the drill and with this heated end we melt the perforation in the lid, in a shape resembling a butterfly or bow. To secure the resulting hole shape, carefully rotate the lid along the spiral grooves of the metal drilling tool. The shape of the hole in the second cover can be round and correspond in size to the diameter of the drill being sharpened.

We place a dull drill, intended for the sharpening process, into the holes of the covers. After which, we must make sure that the drill, when rotating, rotates according to its spiral grooves, and not in some other way.

Our last operation consists of gluing the covers to the base of the inclined surface of a wooden wedge, which, in turn, is secured with glue to a wooden parallelepiped block of appropriate sizes, aligning the tip of the wedge with the end of the rectangular block.

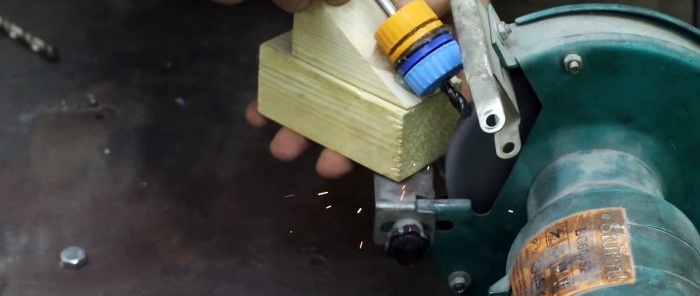

We sharpen the drill on the emery wheel of the sharpening machine, periodically turning the drill clockwise and counterclockwise. The main thing is to firmly press the base of the jig to the work table or the stop of the sharpening machine.

High-quality and durable drills on AliExpress at a discount - http://alii.pub/5zwmxz