Making a high-quality and tight end connection of a square profile pipe that is obviously larger in cross-section compared to a round one is quite a difficult task. But, if you prepare the end of a square pipe in a certain way, taking into account the ratio of the sizes of the workpieces to be connected, this will not be difficult to do. Moreover, this does not require special theoretical knowledge and practical skills. Any adult who knows how to hold an angle grinder in his hands can handle this kind of work.

Will need

Materials and tools:

- round pipe;

- profile square pipe;

- marker and ruler;

- vice and grinder;

- hammer.

The process of tight end connection of a profile square pipe with a round pipe

We take a round pipe that fits freely in a square one. The dimensions of these blanks can be arbitrary. For a specific quantitative calculation, we use a profile square pipe measuring 40x40 mm and a round pipe with a diameter of 27 mm.

We determine the centers of all four sides of the square pipe, which are 20 mm from each of the corners, and mark them on the end sides. We set aside 20 mm from the edge of the pipe and draw a transverse line along the entire perimeter of the square workpiece. On this line we also mark the center of each side. We connect the points of the centers of the sides with vertical lines.

On each of these vertical lines we set aside a distance of 13.5 mm from the end of the square pipe, which is the radius of the round pipe. We set the same size aside from the center of the sides at the end in one direction and the other. We apply the end of a round pipe to the resulting three points on each side and connect them by circling the outside of the pipe with a marker.

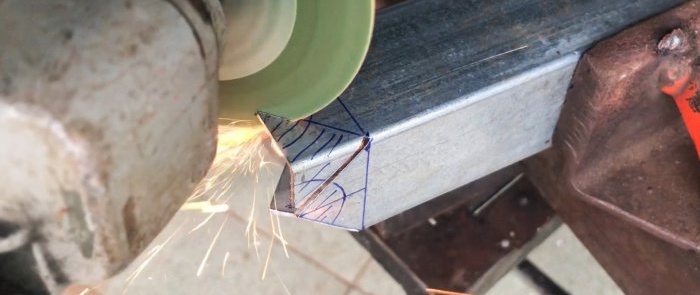

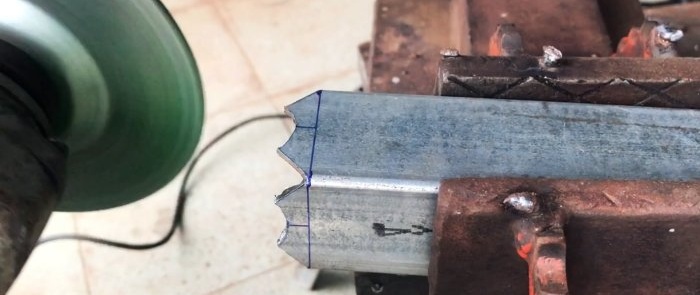

Then we connect the center points of the sides at the end with the ends of the lines spaced 20 mm from the edge of the profile pipe. We remove the shaded areas on each side using a grinder. As a result, the round pipe should fit snugly into the cylindrical recesses on opposite sides of the square pipe in two transverse orthogonal planes.

Using a grinder, we make shallow guide slots along the bases of the remaining fragments from the outside to facilitate their bending inward under hammer blows until all the end fragments take a horizontal position.

Long-lasting discs for angle grinders on AliExpress at a discount - http://alii.pub/61bjly

We insert a round pipe into the resulting round hole, which exactly corresponds to the outer diameter of the pipe.