A screw jack can be assembled from available and inexpensive materials and mass-produced products. To make it, you need at least basic skills in working with metal and the ability to handle universal metal tools.

Will need

Materials:

- lead screw;

- regular extended nut and plug nut;

- channel and strip;

- round rods of different diameters;

- 2 rolling bearings;

- round stainless steel pipe;

- rod with external thread.

Tools: marker, vice, grinder, welding machine, tape measure, drilling machine, grinder, socket ratchet.

The process of making a screw jack from available materials

We lay the extended nut parallel to the flanges in the center of the channel web. We measure the distance from the nut to the shelf and cut 2 pieces from a round rod of the same length. We weld them to the nut on opposite sides.

We screw a nut with welded sections onto the lead screw, onto which we put the bearings.

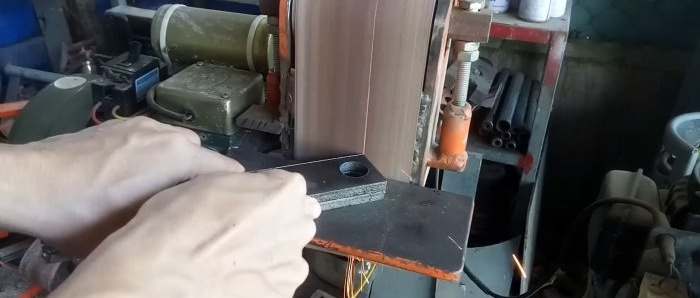

We cut 2 pieces of 20 cm long from the strip, which we attach in two places by welding.We drill holes in them on both sides and round the corners.

From a round stainless steel pipe we cut a fragment with a length equal to the height of the channel and weld it transversely to the end of a longer stainless steel pipe.

We insert a rod with an external thread of slightly longer length into the short transverse tube. We put support-ears on the ends of the rod, and place the entire assembly above the channel lying on the jumper, so that the supports are outside the shelves and weld them in this position. We also weld the ends of the threaded rod to the ears.

To a long stainless steel pipe located longitudinally inside the channel, we weld bosses made from sections of a round rod horizontally on both sides, onto which we put washers and 2 strips, the other side of which is put on the bearing axis with washers. We weld the outer washers to the bosses and the axle.

We weld a plate with a hole in the center for the passage of the lead screw to the end of the channel with the ears. Now, when the extended plug nut is rotated to the right, the screw is screwed into the nut of the bearing assembly and moves it along the channel towards the plate. At the same time, the long levers are raised and the stainless steel pipe is lifted through the bosses.

At the end of the stainless steel pipe, we drill a horizontal hole and, using an axis passed through it and two ears, we weld a self-aligning support heel with a notch to interact with the lifted load.

It is more convenient to rotate the screw with a ratchet wrench.