How to expand the functionality of pliers with just one hole

If you drill a through hole in the center of the pliers in front of the hinge, then with its help it will be easy and convenient to cut rod parts such as nails, rods, knitting needles, etc., the diameter of which does not exceed the diameter of the hole drilled in the pliers.

How to use a steel rope to secure a small drill bit in a drill chuck

Sometimes, due to the small diameter of the drill, it is impossible to secure it in the chuck of a drill or screwdriver. If you first insert such a drill inside a small piece of six-strand rope without a core, and then secure the rope with the drill in the chuck, you can easily get out of this difficult situation.

How to make a simple but reliable clamp from a nut and steel tape

In a standard hex nut, we make cross cuts on both sides without connecting them.

If you now take a piece of metal tape of the required length with an edge bent at 90 degrees, insert the other end into the cut of the nut and screw the bolt into it until it stops, you will get a simple but very reliable clamp.

How to Reveal Symbols on an Old Instrument Using a Marker and a Cotton Swab

Sometimes it is very difficult to read the characteristics or brand of a long-life tool due to surface oxidation and contamination. The task will be much easier if you paint over the symbols with a fresh marker and then wipe this area on the instrument with a cotton swab.

How to make a marking compass from an ordinary bolt and a perforated strip

Using sandpaper, we round off the hexagonal head of the bolt, leaving a thin belt at the bottom.

We cut off the rod just below the head and form a sharp protrusion in the center. We throw a strip with holes along the length onto the rest of the rod and fix the rounded head of the bolt at the desired point of the part to be marked. Insert a marker into one of the holes on the bar and draw a circle or part of an arc.

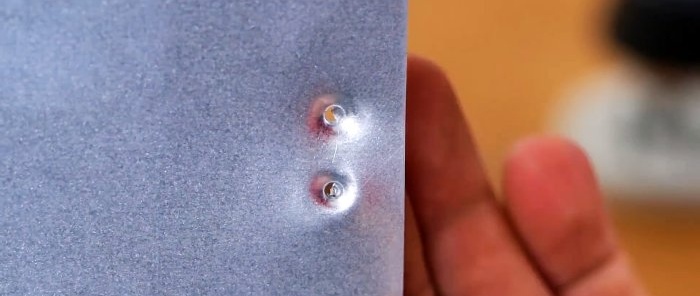

Drilling holes in a metal sheet using sandpaper and a drill shank

Using superglue, glue one layer of sandpaper to the plastic pipe and cut it into pieces.

Now, using a suitable mandrel, we drill out the holes in the metal. This can also be done using the shank of an unusable drill bit clamped in the drill chuck. We set high speeds and firmly press the shank against the hole that needs to be increased in diameter. The hole is formed with the formation of annular beads on both sides.

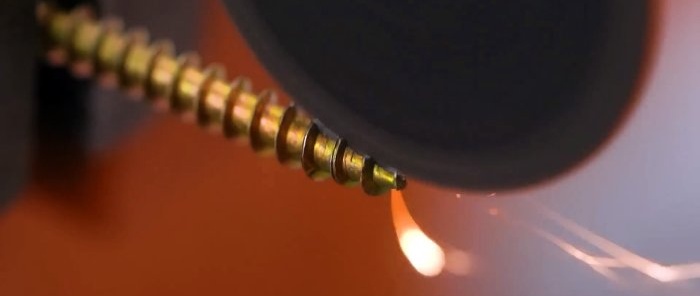

How to flare the end of a tube using a self-tapping screw with a ring head

We clamp the self-tapping screw in the drill chuck, turn on the speed and press the annular head of the self-tapping screw to the end of the fixed tube with some pressure.

After some time, the end of the tube will expand in the radial direction and will ensure the strength and tightness of the connection.

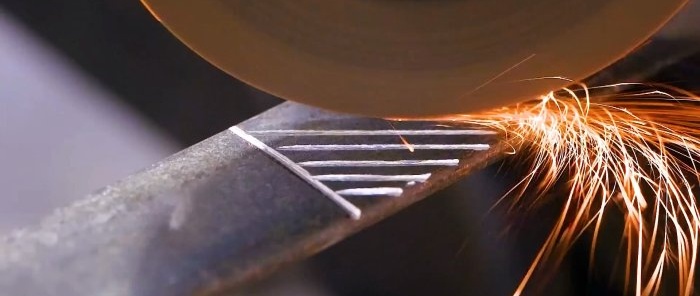

How to firmly screw a bolt into a hole if you don’t have keys

To do this, we clamp the bolt in the drill chuck and turn the hex head of a standard bolt on sandpaper into a flat cylindrical head.

Using a grinder, we make a slotted groove on it. Now we can screw a bolt with such a head into the hole using a flat washer of suitable thickness.

How to make a tool for punching holes in tin from a stationery stapler

We remove the lower plastic casing and washer from the office stapler, and drill out the outer hole in the groove of the stapler into which the staples are inserted to the diameter of a bolt with a cylindrical head and a pointed rod.

We secure the bolt from below with a nut to the gutter. Now with the help of such a stapler you can easily punch holes in tin sheets.

How to easily turn an ordinary screw into a self-tapping screw

Using a grinder, we make slots in the longitudinal direction on the 3-4 end turns of the screw.

As a result, the screw turns into a self-tapping screw and is easily screwed into blanks made from the densest solid wood.

How to turn a metal rod with a handle into a wire wrapper

We sharpen the end of the rod on sandpaper, heat it in the flame of a gas burner and, stepping back a little from the end, bend it at 90 degrees with pliers.

Now, with the help of such a simple tool, you can reliably fasten workpieces with twisted wire.

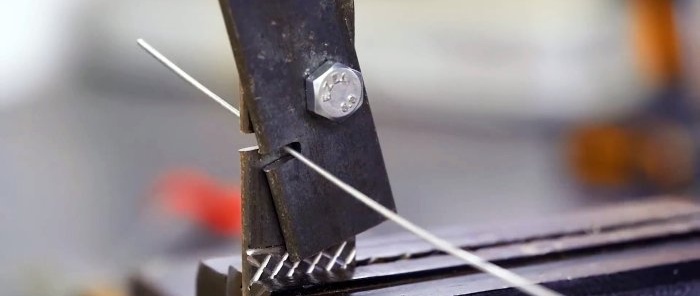

How to make a cutter for wire and thin knitting needles from two plates and a bolt with a nut

We make a double notch on part of the steel plate. We apply the same plate along the length, starting from the notch. Above the notch we make shallow slits in the plates.

Above the slots, closer to the opposite edge from them, we drill holes and connect the plates with a bolt and nut. We clamp the edge of the plate with notches in a vice. We place the wire in the aligned slots, turn the plate around the bolt and the edges of the slot will easily cut the wire.