First of all, we list all the necessary tools and consumables:

1. Board 10*2.5 cm.

2. Rail 3*2.5 cm.

3. Fasteners (screws of various lengths)

4. Welded and punched mesh with a cell from 0.5*0.5 to 1*1 cm.

5. Tools (circular saw, jigsaw or hacksaw, drill, screwdriver for convenience, hammer, stapler, it is possible to use additional tools)

The frame can be made of either wood or a metal square pipe. Metal is more durable and hygienic.

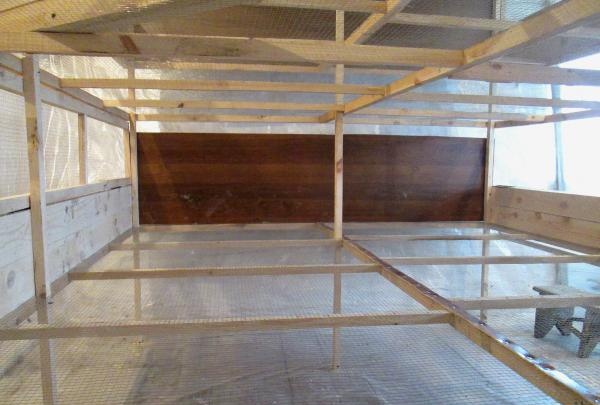

Let's start with the base, these are four identical mesh panels on a durable frame. Each of them will be either a floor or a ceiling for the “kids”, forming 2 tiers. Dimensions 195*260 cm. The length can be changed, but in width a size larger than the specified one is strictly not recommended.

In this case, the welded mesh is fastened with a stapler with a twist at the ends at the edge and in the middle.It is very important to make the tension as effective and durable as possible. A more reliable option against sagging would be a punched mesh. It will provide increased rigidity.

We prudently treat the joints in the middle with a protective material so as not to injure the chickens’ paws, for example, with a strip of linoleum.

We make slots in the mesh for the racks in the same places and lay all four sheets with the mesh up on the prepared floor. It is worth taking care of the walls so that there are no drafts.

We insert the racks all the way into the floor into the prepared slots, and fasten them to the ceiling strictly vertically in level.

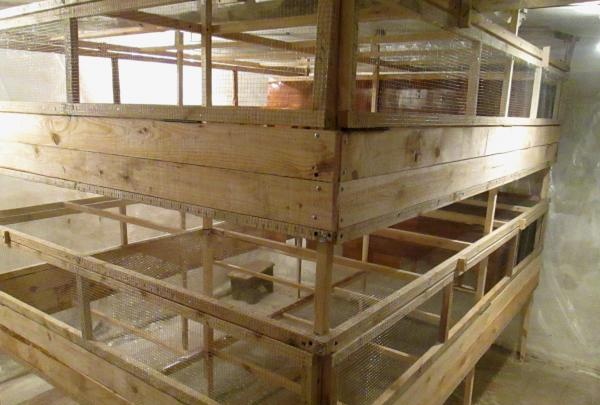

The next step will be fixing the ceilings and floors. The overall width of one tier was 58 cm. Between tiers there is a minimum of 22 cm, however, if you use pallets to collect litter, which will undoubtedly facilitate removal of litter, then less is possible.

The distance between the floor of the lower tier and the zero floor is 52 cm.

Sew up the sides. There are two 10 cm boards on the bottom and a transom on hinges on top.

Our chicken coop is ready. All that remains is to make electrical wiring for 3 - 5 light bulbs for each level.

We lay newspapers, burlap or plastic film on the ceiling of the lower level and on the ground floor for easy collection of droppings.

For a comfortable life for yellowmouths, you can build a heating tank by fencing off 60 cm on one side with a separate box.

Practice has shown that the temperature in the heating room is only two degrees higher, i.e. if there are no drafts in the room, then you can do without it.

The structure can be disassembled and installed in another location if desired.

Front view of the heating tank inside the tier.

Heater side view.

Do not forget about safety precautions when making wiring for light bulbs.The cartridge should not come into contact with flammable materials and be at a distance of 10 cm from them.

Each tier of such a chicken coop can support up to 100 kg of live chicken weight.

The chickens will be delighted!