Signs of damage.

Many manufacturers have the same error codes stored in the intelligent part of the washing machine. If you find on the displays, upon startup, the inscription F 08 (for electronic devices), or the indicators are constantly lit: “Number of revolutions”, “Quick wash” (for electromechanical devices), it means that the equipment is faulty and its further operation is impossible.

Algorithm for the operation of mechanical and electromechanical devices.

Machines equipped with an electronic control board will display an error at the beginning of the wash cycle, after the pump is running. Since at this time, the electronic module checks the main electrical components: a tubular electric heater (TEH), a water level pressure switch, an electric water valve, etc. In mechanical units (machines manufactured before 2000), this failure manifests itself in the form of a cold water during the washing process.

Causes of malfunction.

Error F 08 occurs due to damage:

- electric heater (in 80% of cases);

- water temperature sensor (in 8% of cases);

- heater control relay (in 12% of cases).

The heating element and temperature sensor break down if:

1. They are made from low quality materials.

2. Has local overheating due to the formation of a non-metallic layer (scale, foreign objects) on the working surface.

3. Voltage greater than 240 volts is supplied.

The control relay may be damaged if the device is connected to an unstable network (when the voltage constantly changes from 160 to 260 volts). In this case, there is a breakdown in the electrical connection between the mains power supply and the heater due to charring of the power closing contacts, and since the relay is enclosed in an opaque housing, it will not be possible to visually detect the breakdown.

Troubleshooting a node.

To determine damage to electronic components you will need: a measuring device with an ohmmeter function and testing semiconductor devices.

Step #1.

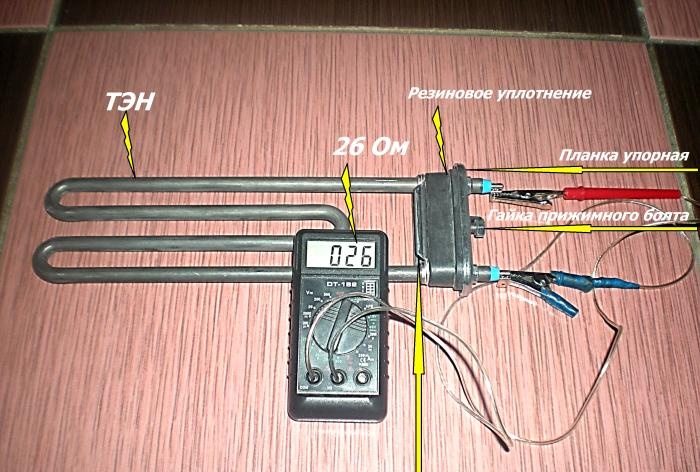

Since, in most cases, the heating element in the machine breaks down, this means that it must be inspected first. The heater is located at the bottom of the tank, at the front or rear of the machine.After detecting it, disconnect the neutral and phase wires from the contact group. Connect to them multimeter in "Ohmmeter" mode. If the readings are:

- 0 - there is a short circuit in the heater circuit, between the body and the heating wire;

- 1 - there is an open circuit in the heater circuit;

- 25 - 30 Ohm - the heating element is in good condition.

To examine the relationship between the heater contacts and its metal tubular shell, the tester switches to diode testing mode. One probe is alternately connected to the electrical terminals of the heating element, the other to its body. When the metal shell and the spiral are short-circuited, the tester will begin to make sounds (squeak) and show a resistance of 0 Ohm.

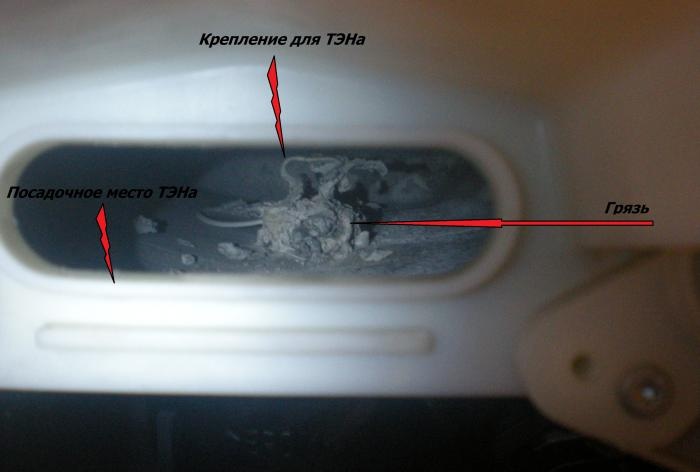

If a breakdown is detected in the heater, it must be replaced with a working one. To remove the heating element from the washing machine: unscrew the nut of the clamping bar bolt so that the nut covers the beginning of the bolt thread. It is located near the temperature sensor. Strike the nut with a hammer until it moves to the heater stop bar. Grasping its contact with pliers, applying vertical and horizontal forces, pull out the worn part. Clean the seat of the heating element from the outside and inside the drum from dirt and scale. Dismantle and install the temperature sensor from the removed electric heater to the one being installed. On it, move the pressure bar away from the thrust bar as far as possible. In this case, the nut should be at the end of the bolt. Once in the latches for the heater, which are located inside the sealed drum (such heater fastening is used only in old-style machines), install the heating element until the stop bar touches the housing. Tighten the nut until the heater is securely fixed in the seat. Connect electrical wires to the mounted unit.Assemble and test the operation of the equipment.

Step #2.

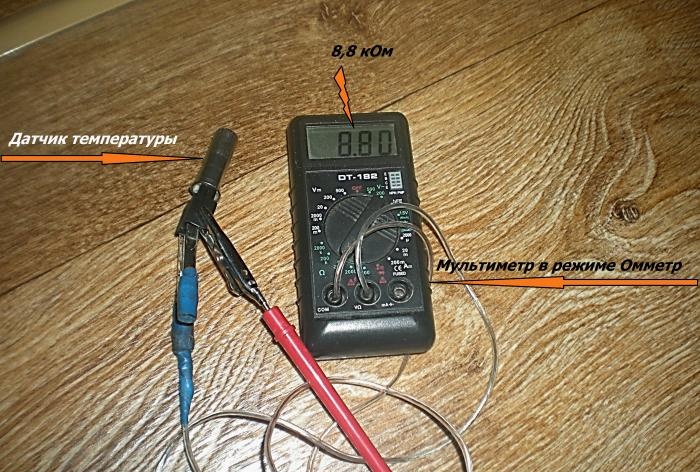

A water temperature sensor is built into the thrust bar and rubber seal. Under the influence of temperature, it changes its resistance. To check it:

1. Disconnect the connector from the contact group.

2. Using a tester, determine the resistance of the part.

The readings of a working sensor will change downward as the ambient temperature increases. At a temperature of 20 degrees Celsius, depending on the sensor model, the resistance is in the range of 5 - 6 kOhm, at 50 C0 - 1300 - 1400 Ohm.

If the measuring device shows 0 or 1, then the sensor must be replaced with a working one. For this:

- unscrew the nut of the clamping bolt until it starts;

- strike the nut until it moves to the connecting bar;

- remove the damaged sensor;

- install a working sensor in the vacant seat;

- tighten the nut until the heating element is securely fixed;

- connect the plug with the wires.

Step #3.

On the control board, determine where to install the relay. It is easy to find by the wires connected to the heating element. The relay consists of a control (electromagnet) and a power part (powerful moving contacts). To detect a breakdown, it is necessary to check the resistance of the inductor, which is in the range of 175 - 190 Ohms, and the condition of the contacts. The relay must be replaced if:

1. The electromagnet has a short circuit or open circuit.

2. Contacts do not conduct electric current when closed (oxidation, charring of working surfaces).

3. The contacts are always in the closed position (sticking).

If one of the above types of breakdowns is detected, the relay must be replaced.

Relay replacement sequence:

- using a soldering iron or an electric soldering gun, disconnect it from the circuit board;

- free the mounting holes from tin;

- on the board, install a new relay;

- Using flux and tin, solder the contacts securely to the tracks.