Using a band saw, you can cut flat pieces of varying thicknesses. Only, unlike a jigsaw, both hands are free to operate this equipment, and a comfortable wide bed is offered for moving the workpiece. Most often, a band saw is used to cut blanks of complex curved lines.

Working principle of a band saw

Two disk-drums are fixed on the vertical frame, transmitting torque from the engine to the metal sawing belt. In the sawing area on the bed there is a work table placed horizontally. The workpieces move along it and are sawed according to the principle of a jigsaw.

We prepare materials and tools

Materials:

- Plywood 16-18 mm;

- Bearings for the diameter of drum shafts;

- Threaded metal studs for shafts, diameter – 10-12 mm;

- Sawing tape;

- Insulating tape;

- Bolts, nuts, screws, wood glue or PVA.

Tools:

- Jigsaw;

- A circular saw;

- Drill or drilling machine;

- Sandpaper for wood;

- Clamps;

- Tape measure, pencil, sandpaper.

Making a band saw

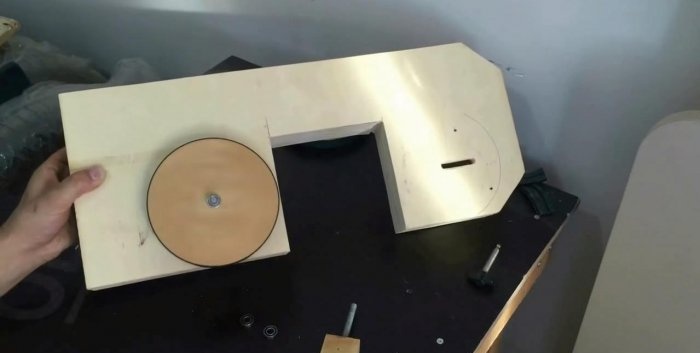

Our machine will be made almost entirely of plywood. Therefore, for the base frame, we cut out four identical strips of plywood using a circular saw or a jigsaw, as shown in the photo. It is advisable to take a larger thickness.

Using a jigsaw, we cut out the grooves for the tensioner, frame and drum mounts. To make the holes and grooves more identical, you need to fasten the parts together with a clamp in pairs before sawing. As a result, we should have two pairs of different frames.

Now you need to glue the plywood with wood glue or PVA and connect all the parts of the base. For better crimping, you can press the edges of the gluing together with clamps.

We make a tape tensioner from a small wooden block or two pieces of plywood spliced together. It should fit tightly into the groove as if along guides. We plug it with a wooden strip so that the tension screw passes through it, securing it with self-tapping screws.

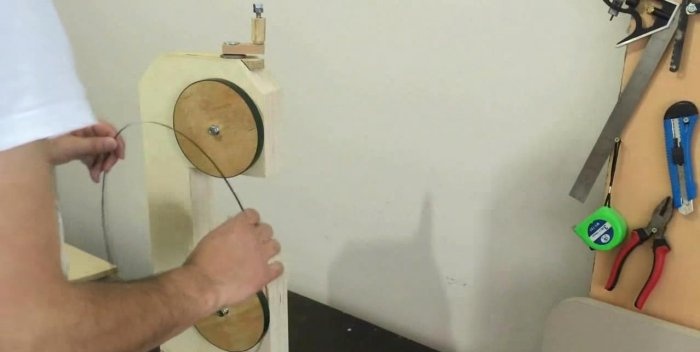

The remaining plywood will be used for drums. Having marked them, we make a hole for the shafts, and then cut them around the circumference with a jigsaw. We level and clean the edges of the plywood with wood sanding. To prevent the tape from slipping, the author preferred to seal the ends of the drums with electrical tape.

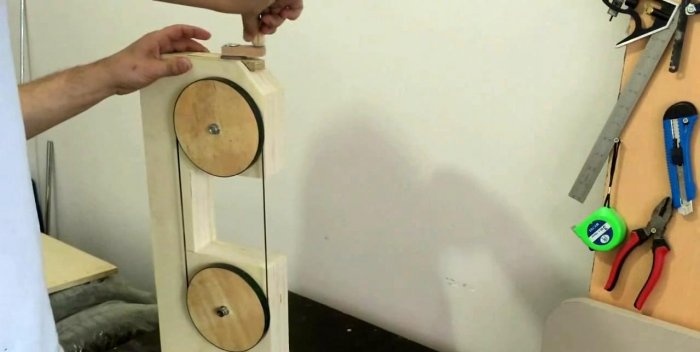

We install bearings at the shaft landing site. Two of them will be on both sides of the frame for the fixed drum. The remaining two are located on the tensioner. We also install a locking bolt to secure the tensioner from the rear of the frame.

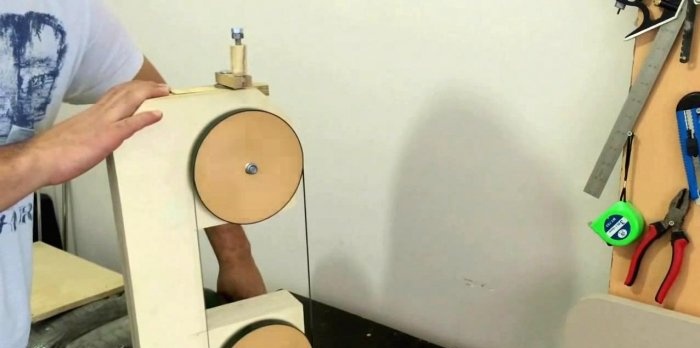

We fix both drums on the frame so that they can move freely on the shafts without catching the machine body. We tighten the sawing band and adjust the tension using the tensioner, while simultaneously securing it with a stopper. Since the band saw is designed for vertical sawing, it is necessary to attach a lower platform made of a wide board or piece of plywood to it for stability. In the cutting area you also need a work table on which the workpieces will move.

The machine is ready and you can try it in action. We clamp the lower shaft of the drum into a screwdriver or drill, and give the machine speed. Despite the low power of such a device, it can be used to cut parts from plywood, boards, MDF or fiberboard in a home workshop!

Practical advice

- The machine speed should be selected experimentally, starting with small ones.

- Watch the movement of your fingers, since the majority of injuries in carpentry are caused by such machines.

- In large factory machines, the drums are protected by covers so that only the cutting table area is exposed. It is also worth attaching to such a device additional means of protection against tape rupture, which, unfortunately, are not specified by the author.

Good luck to everyone and bye!