A more affordable tool for many amateur craftsmen is an electric drill - a fairly compact device, easy to use and affordable.

The main purpose of this device is to drill and ream holes in various materials. But there are many homemade devices with which you can perform milling operations on wood and wood materials using an ordinary drill.

Below we will consider one of the possible options for such a device, almost entirely made of wood. Let's see what tools we need for this?

Required tools and materials

The drive for almost all the tools we use is a drill, for which we make a device for milling operations. We will need the following instrumental positions:

- circular drill (“ballerina”);

- twist drill;

- feather drill (“perka”);

- core drill (“crown”);

- hacksaw for metal;

- sandpaper;

- milling heads;

- ruler and marker;

- clamps.

As a blank for making parts of the device, we use a piece of hardwood board (oak, beech, birch, etc.) 25-30 mm thick. Also, to fasten the homemade elements, we will need screws (screws), bolts and nuts of the appropriate diameter and length.

Making a device for milling with a drill

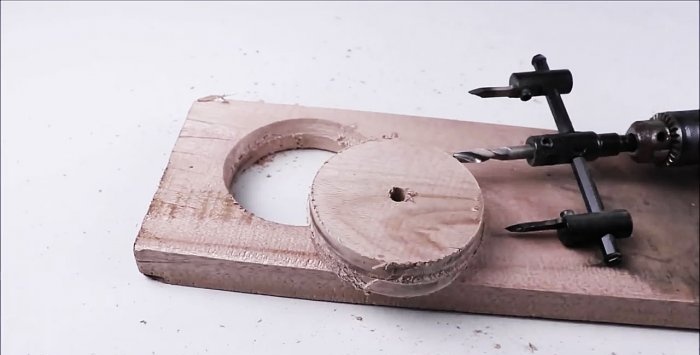

Without hesitation, let's get to work. We lay the blank board on a flat base. We fix the shank of a circular drill in the drill chuck and cut out two circles of the required diameter one after another (100-120 mm).

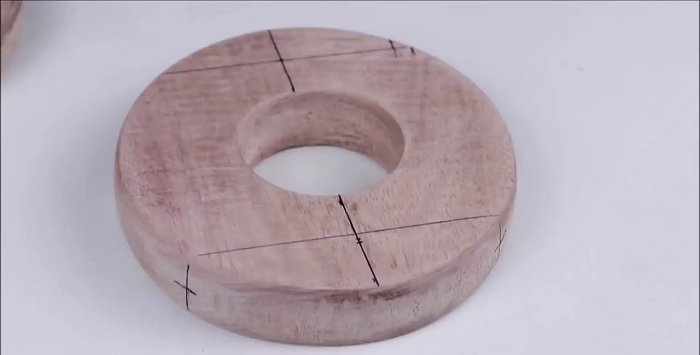

We place each of the cut circles on the mandrel in turn, fix it in the drill chuck, turn it on and use sandpaper to grind the forming parts of the wooden disks.

We secure the circles with clamps to a reliable base and, using a core drill, drill a hole in their center with a diameter equal to the size of the part of the drill body adjacent to the spindle (about 50 mm).

We also process the resulting holes with sandpaper.

We make another hole under the neck of the drill.

We mark one of the disks so that we get four identical cutouts, symmetrically located around the circumference.

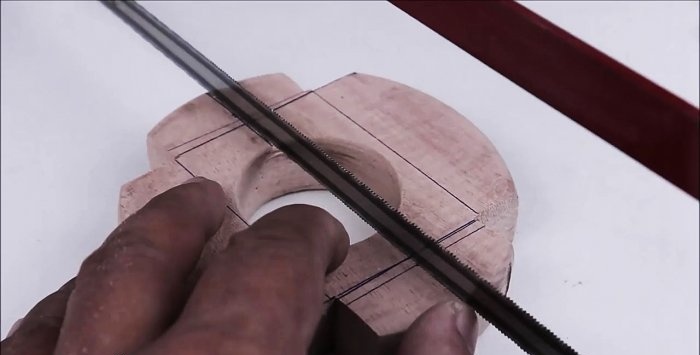

Moreover, the cutouts should be limited by perpendiculars that do not intersect in the center of the circle. We cut out the marked elements with a hacksaw.

We fasten the circle with cutouts “on the edge” with clamps and on the horizontal shelves we drill successively recesses for the nuts and, as their continuation, through holes for the tightening bolts, respectively, using a spade and twist drill.

Next, use a hacksaw to cut this workpiece into two symmetrical parts (halves).

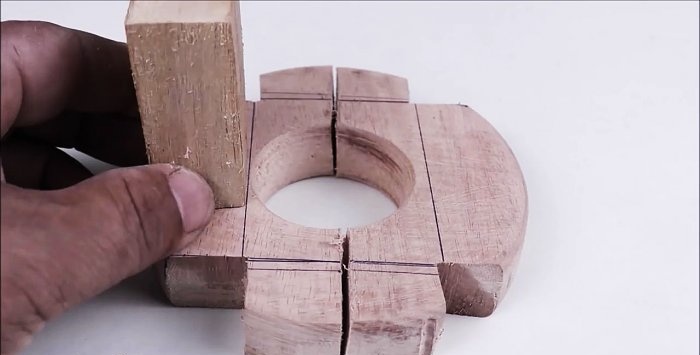

Using a pair of identical blocks of the required height and cross-section, as well as appropriate markings, we connect it with screws to the second circle.

First, we tighten the halves of the circle with the cutouts with bolts and nuts. We fix all the heads of the used hardware flush.

Top:

Bottom:

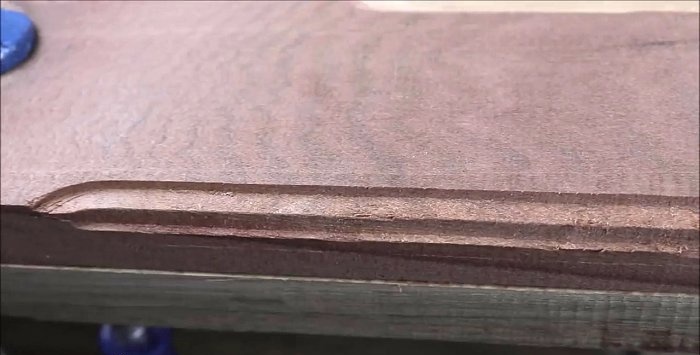

All that remains is to attach the device we just assembled to the drill, and in its chuck - the milling head, and you can easily and simply make any shaped grooves in wooden parts.

We insert the cutter into the chuck.

We put on the device.

And we mill.

The cutter may be different.

Operational safety and improvements

Since the “ballerina” and especially the core drill create a large torque during operation, for safety reasons it is better to securely fasten the workpiece when cutting circles and holes using the same clamps. You should also wear safety glasses and gloves on your hands.

In order to make it easier and more convenient to work with our homemade device, it is better to screw wing nuts onto the bolts that tighten the “clamps” on the drill instead of ordinary nuts. Tightening and unscrewing wing nuts is undoubtedly easier and faster than standard nuts.

Also, work on the device will be simplified if, instead of spiral and spade drills, you use a combined furniture drill (it simultaneously drills a recess for the head and a through hole for the fastener rod).