If you have a steel rod, you don’t have to buy a chain and bend it from it. To do this you will need to make a simple machine. It can literally be assembled from scrap metal and pipe scraps.

Materials:

- large bearing;

- shaft for the inner race of the bearing;

- profile pipes 15x15 mm, 30x30 mm;

- M6-M8 stud or long bolt;

- nuts M6-M8 – 2 pcs.;

- strip 20x3 mm.

Machine manufacturing process

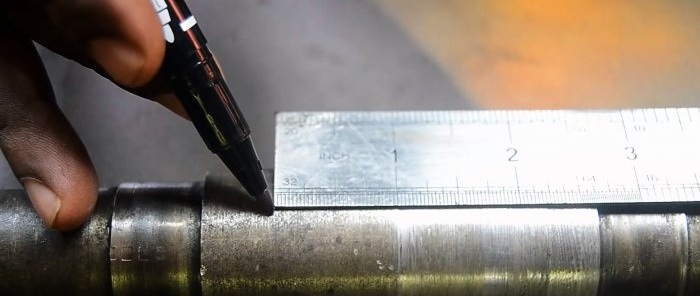

It is necessary to select a shaft to match the diameter of the inner race of the existing large bearing. A small piece of 10-15 cm is cut from it.

It is drilled 25 mm from the edge with a 6-8 mm drill.

From the end, using a grinder, you need to cut a groove to the hole.

One of the tenons at the end of the shaft needs to be rounded on one side, and the circle must be cut to the depth of the groove. It is he who will set the shape of the chain link. The wider and longer the tenon, the larger the link. After the grinder, it should be trimmed with a file.

The shaft is pressed into the bearing. Then it needs to be welded onto a section of profile pipe. It is simply needed to hold the machine in a vice.

A long lever is welded to the bearing, which will be used to bend the rods into links. Opposite the groove, a finger made of round timber equal to the length of the tenons is welded to the bearing race. A small gap is made between them to insert the rods.

A piece of strip is welded obliquely onto the lever. You need to weld a nut onto its edge and screw a pin or long bolt into it. It will serve as a limiter for the rod in order to position it correctly when bending the link. You can fix the position of the bolt with an additional nut.

To use the machine, you need to cut rods of the same length and clamp it in a vice. The position of the limiter is calculated empirically.

Then the first link is bent. After it makes one bend of the next one. The workpiece is connected to the previous link and bent into a ring.

The entire chain is made in this way. If necessary, the links are trimmed with a hammer, after which it is advisable to secure them with a drop of welding, so they will definitely not bend.

Watch the video

How can I drill a bearing without any problems? - https://enn.washerhouse.com/4428-chem-prosverlit-podshipnik.html