When welding metal structures from profile pipes, it may be necessary to make the outer corners rounded. They look better and are also less dangerous. To obtain them, there is a special technique.

What you will need:

- Square;

- compass;

- Bulgarian;

- welding machine.

Round corner welding process

A rounded corner is formed by special bending of one pipe, and not by welding two like a standard straight one. To do this, you need to draw a transverse line on it using a square.

Then, on the side of the future internal corner from this line, a point is marked at a distance of the width of the pipe. In this case, it is 5 cm, so the mark is placed with an indentation of 5 cm. Now you need to move the compass apart by 5 cm, and connect the point and the edge of the line, drawing a quarter circle.

Next, you need to mark a second one behind this point, at a distance from the line equal to the distance of the drawn circle. You can simply take a grinder disc with the same rounding, attach it to the drawn arc, and put marks along its edges.Then it is installed at one point at the beginning of the line, and rolled along the pipe. The mark we need is placed at the point where the second point touches it.

This distance can also be calculated mathematically using the circumference formula “P=2πr”. Where r is the radius of the circle, which in our case is always equal to the width of the pipe. The distance that needs to be retreated from the line will be equal to a quarter of the circle calculated by the formula.

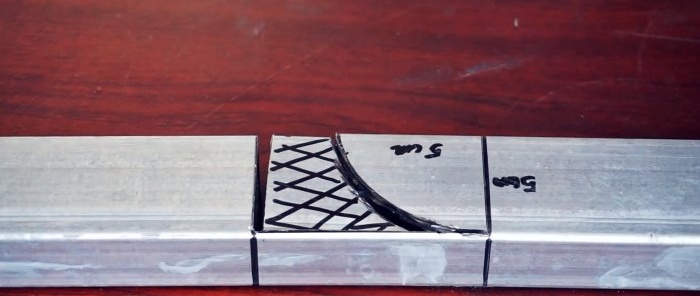

At the last mark on the pipe, another transverse line is drawn under the square. Now you need to shade part of the pipe, as in the picture. Do the same on the other side of the pipe. You will also need to shade the short rectangle on the side wall.

The marked shaded part of the pipe is cut off.

The edges of the cut need to be sanded.

After this, the pipe is bent.

It will resist, so you can knock it out with a hammer and hold it for tack welding.

Next, the joint is welded with a continuous seam.