The quality of welding work strongly depends on the preparatory procedures, including the fixation of the workpieces being welded, which can be disrupted by touching the electrode. To eliminate this negative, there are magnetic holders, a set of which costs a lot of money. But you can make them yourself from readily available materials and some skills in handling metal tools. This magnetic corner holder is capable of fixing parts at any angle; similar models cannot be found on sale.

Will need

Materials:- Steel equal angle;

- round magnets with a central hole -

- steel bushings;

- brass bushing;

- bolts, screws, washers and nuts;

- metal handle-lock.

Manufacturing process of a universal magnetic holder for welding work

From a steel equal-angle angle we cut two fragments of the same length.

We mark them and use a band saw to give them the required configuration.

In one of the shelves of the corner pieces, we make two holes, first with a spiral and then with a core drill of the appropriate diameter. They will be needed to install round magnets.

We weld the inside of the hole with washers with a diameter slightly larger than the diameter of the holes.

From two steel bushings and one brass bushing, which freely fits into the internal holes of the steel bushings, as well as a bolt, washer and nut, we assemble a hinge.

We weld the bolt head flush with the end of one of the steel bushings and grind the welding area with a grinder.

We weld the corner blanks tangentially and in the same plane, one to the top, the other to the bottom bushing with the part of the shelf with the cutout.

Core bushings for installing angles at the required angle without additional actions.

In the holes welded at one end with washers, we install round magnets with a central hole and secure them with countersunk screws and nuts to the welded washers.

Instead of a nut, we screw a knurled locking handle onto the hinge bolt.

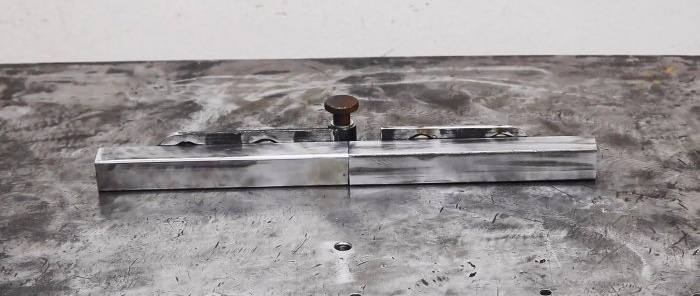

The design of our magnetic holder allows you to install its wings at any angle from 30 to 180 degrees. To do this, just release the hinge, set the required angle and again fix it in the desired position with the locking handle.

Our homemade magnetic clamp reliably holds and fixes the workpieces to be welded in the desired position for the entire duration of the welding process.