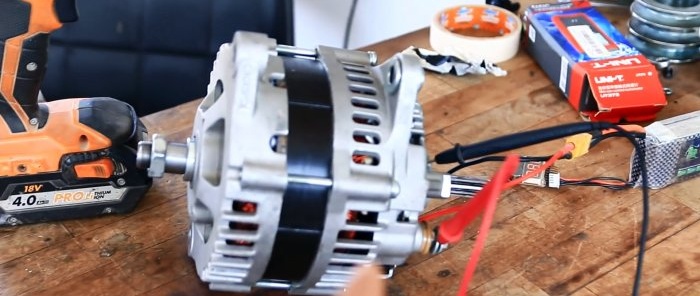

The most affordable ready-made generator for assembling a wind generator is a car one. You can buy it for almost nothing at a salvage yard. The only problem is that it generates energy only when the rotor winding is excited. For this reason, you can make a full-fledged wind generator from it by slightly altering the armature, or by powering the excitation winding. Let's look at how this is done in the second way.

Materials:

- Car generator 24 V;

- steel square 20x20 mm;

- pipes 50 mm, 20 mm;

- round timber 20 mm;

- strip 20 mm;

- sheet steel 3-5 mm;

- bearings – 2 pcs.;

- profile pipe 20x40 mm;

- plastic sewer pipe 110 mm;

- screws, nuts, bolts.

Wind generator manufacturing process

In order for the generator to operate without a car, its field winding must be powered directly from the battery. To do this, wires are soldered to the graphite brushes, which will later need to be routed to the battery.

Then you need to weld the generator mounting frame. With its help he will be held on the pole. The frame is welded from a square.It provides mounting brackets for the standard generator lugs.

To install the frame with the generator on the pole, you need to weld a tube to it and press two bearings into it. There will be a large load on this node, so you need to make two support points.

A piece of strip with a bushing is welded to the tube with bearings, on which the rotary tail will be installed. It is needed to guide the blades with the wind. The ability to rotate will allow him to adjust the position so that the blades do not spin too much. This will protect the generator and other equipment from damage.

To attach the tail, a finger is made from round timber that will fit into the bushing. A hole is made in the end of it and a thread is cut so that it is fixed with a bolt and washer and does not fall out of the sleeve. The base of the tail from a section of profile pipe is welded to the pin.

Holes are drilled on it for attaching the tail blade.

Then you need to tackle the impeller frame. It is a disc made of sheet steel. It needs to be drilled for attachment to the generator shaft, as well as for the brackets of the five blades. The latter are made from steel strip and are also drilled.

Then the attachment is made to the pole. It is a disk with a welded shaft that will be inserted into the bearings. The disc is drilled in several places to screw it to the pole. A hole is made in the shaft at the end and a thread is cut into it. It will be needed to tighten the bolt and washer to prevent the fastener from falling out of the bearing race.

The impeller blades and tail blade are cut from a plastic sewer pipe.

The shorter they are, the higher the generator speed will be.But if the wind is weak, then only long blades can rotate it. It is better to initially make them large, and then, as a result of experiments, shorten them to an acceptable size.

The wind generator is assembled and installed on a pole as high as possible, where nothing stops the air flow. It is necessary to power the excitation winding from the battery to start generation.

As a result, the charge that goes back to the battery will be more than the winding consumes. Due to this difference, the battery can be recharged.