A bench vise is considered a stationary tool. But sometimes moving it makes the work easier and easier. Anyone can make a mobile vice without loss or limitation of functionality, and this does not require expensive materials or professional skills.

Manufacturing of mobile vices

We measure the seat of the old tire and cut out a bottom from wood material, which we fasten with self-tapping screws to the bead around the circumference.

We also mark and cut out a round disk from the remaining sheet material.

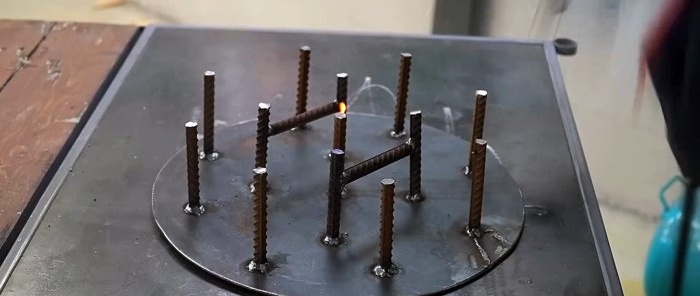

We cut pieces of old reinforcement commensurate with the width of the tire and weld them evenly vertically to one side of the rim. Closer to the center, we connect 2 pairs of vertical segments with horizontal ones.

We will place the disc on the free side of the tire with the reinforcement sections facing down. But first we mix the cement-sand mortar and fill it with the entire internal cavity of the tire, the lower seating hole of which is covered with a bottom made of wood material.

We place a massive oppression on top of the disk and give it at least 48 hours for the cement-sand mortar to harden and wall up the reinforcing pins.

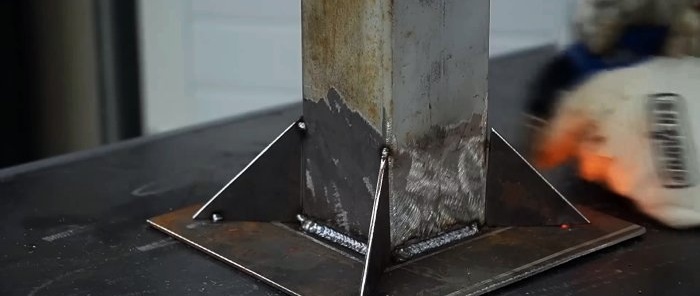

We weld a section of profile square pipe of the estimated height vertically in the center of a square steel plate.

To strengthen the joint and give it rigidity, we weld 4 gussets at the corners.

We turn the resulting assembly over and place the free end of the square pipe in the center of the disk, embedded in the tire, check the horizontalness of the plate along the diagonals and weld the base of the pipe to the disk.

From a profile square pipe of small cross-section, we weld a rectangular frame with one end raised, cover 3 sides of the plate with it and weld it to the plate.

From a profile rectangular pipe we weld a spatial structure of sufficient strength and rigidity, which we weld on one side to the disk, and on the other we attach rolling bearings.

We cut 2 rings from the profile square pipe and weld them to the stand in the middle of the height.

They will hold hammers and other tools while moving the vice from place to place. We drill holes in the corners of the plate and cut threads into them. We paint the structure with metal paint.

Using bolts, nuts and washers, we attach 2 bearings to each post of the supporting structure.

We attach the vice to the plate with bolts.

To move the vice, press the crossbar of the supporting structure with your foot and press the handle to the bottom with your hands. The bearings are in contact with the floor, and the structure is easily moved to the desired location.

Cement-sand ballast gives the tool stability during operation.