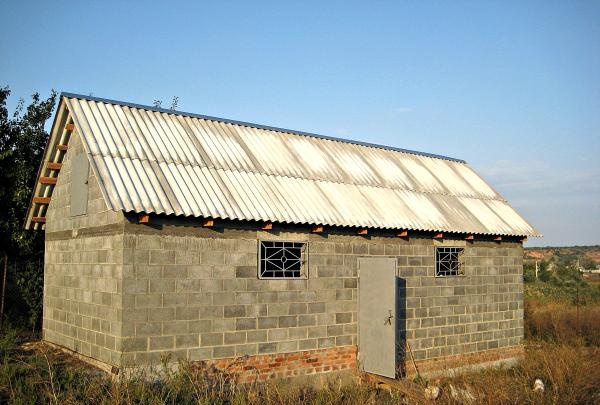

The process of constructing a gable roof.

1. In order to build a roof, we need wood - beams and edged boards.

2. We lay out the beams under the beams along the perimeter of the roof. We use 50*150 mm timber.

3. To prevent the beams from rotting, it is necessary to waterproof them from the wall. To do this, we prepare roofing felt.

4. Bend the roofing material to the required length and cut it using thread.

5. Waterproofing elements for beams are prepared.

6. We install the beams at the distance we need from the edge of the wall.

7. To secure the waterproofing to the beams, we will need a stapler.

8. Place waterproofing under the beam.

9. We wrap the beam with roofing material and secure it with a stapler.

10. We carry out such work with each beam.

11. The distance between the beams must be equal.

12. So that the beams do not move among themselves and it is convenient to move along the future roof, we secure them with boards.

13. We lay out the blocks around the perimeter of the wall for further lining of the beams.

14. We cover the beams.

15. To manufacture the rafter system, you will need a 50*100 mm beam, in which it is necessary to make cuts and cuts at a certain angle.

16. In order to carry out such work, it is necessary to lay out the beams in such a way that they follow the contour of the future rafter system.

17. We measure on the template beam the length at which the extreme points of the rafter sole will be located.

18. We bring the ridge part of the rafters together until the corners of the beam touch.

19. In the ridge part, on both sides, mark the contact lines of the timber with a pencil.

20. In order to make the sole of the rafters, you need to place a beam on top and mark the line with a pencil.

21. The base of the rafters is marked.

22. We saw off along the intended line.

23. The ridge part is marked.

24. In the ridge part we make cuts equal to half the width of the beam.

25. We make cuts with regular frequency from the marked line to the edge of the beam.

26. Using a hammer or ax, remove excess wood.

27. Using a chisel, level the surface of the two beams that will be folded.

28. The beams are folded in the ridge part.

29. The rafters are prepared for installation.

30. In order to install the rafters evenly, it is necessary to tighten the cord.

31. Using this cord as a guide, we drive a nail into each beam.

32. In the ridge part of the rafters we hammer a nail that will fasten the rafters together.

33. We install rafters that will rest against the stop nail.

34. Then we fix the first rafter.

35. We fasten the bottom of the rafters to the beams using 150 or 200 mm nails.

36. We secure the subsequent rafters together using planks.

37. When all the roof rafters are installed, it is necessary to sheath.To do this, we hammer nails into certain rafters along the length of the board (sheathing) at an equal distance from each other.

38. We rest the sheathing board on the hammered nails. We nail the board to each rafter using 2 100 mm nails.

39. The roof sheathing is ready.

40. At the next stage, it is necessary to remove the excess parts of the beams.

41. To do this, use a square to draw a cutting line.

42. Cut off the excess part of the beam.

43. We carry out such work with all beams.

44. Cover the roof with slate and install ridges.