2. Operating principle.

3. Signs of malfunction.

4. Causes of failure.

5. Diagnostics and repair of boiler pressure switch.

Purpose of the pressure switch.

A pressure switch, also known as a smoke pressure switch, differential relay, smoke sensor, is a sensitive device designed to turn off the boiler in case of poor removal of spent fuel. It controls the operation of the fan and, if there is insufficient flow of contaminated air in the chimney, sends a signal to the control board to turn off the gas burners. Such sensors are equipped with gas water heaters with a forced smoke removal system.

Principle of operation.

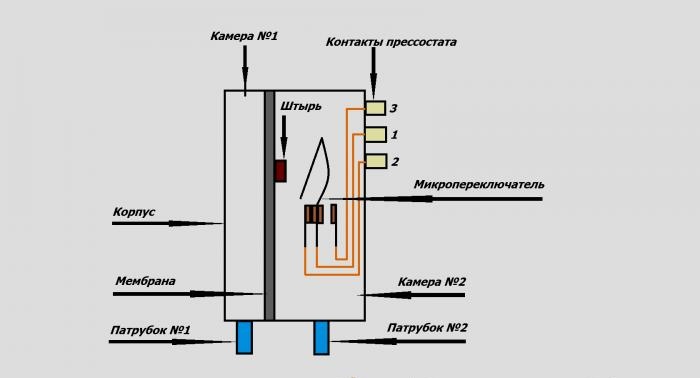

The pressure switch of a gas boiler consists of a housing with pipes, a microswitch with 2 positions, a movable membrane with a pin, which divides the internal space of the housing into 2 chambers.

When the smoke exhauster is not working, contacts 1, 2 are in the closed position (contact 2 is not connected to the control board).When the fan starts, a vacuum occurs in chamber 2, which is transmitted from the rotation of the turbine through the Venturi tube, the tube with the condensate collector and pipe 2, due to which the membrane with the pin is attracted and closes contacts 1, 3 (contacts 1, 2 are open). This signal indicating the normal operation of the smoke exhauster is sent to the control board (contacts 1, 3 are connected to the control module), which ensures that the boiler operates according to a given algorithm.

Signs of malfunction.

If the smoke sensor breaks down, the following symptoms appear:

1. In the differential relay, when the fan is turned on, there is no microswitch click.

2. The boiler does not work and gives approximately the following error: “The air relay is turned off, the fan is working.”

Causes of failure.

The following reasons can cause the relay to break down or malfunction:

1. Oxidation of contacts. When the fan starts operating, a click of the microswitch is heard, but due to the oxidized film on its conductive parts, the circuit does not close.

2. Wear of membrane material. Deterioration of the technical properties of the moving part of the smoke sensor contributes to the disruption of its operation.

3. Clogging, damage or formation of a water seal in the tube with the condensate collector. When cracks or ruptures form on this element, as well as when the tube is clogged or filled with water, the sensor responds inadequately to changes.

4. Reduced fan performance. The attractive forces that arise during the vacuum in the turbine chamber are not sufficient to move the membrane to the microswitch.

Diagnostics and repair of boiler pressure switch.

To identify a faulty node, you can do the following:

- turn off and de-energize the boiler;

- open the front part of the case;

- connect contacts 1, 3;

- reset the error and start the boiler.

If the boiler starts working, it means that the problem is in the pressure switch. To diagnose and repair it, it is necessary to examine the condition of the following elements:

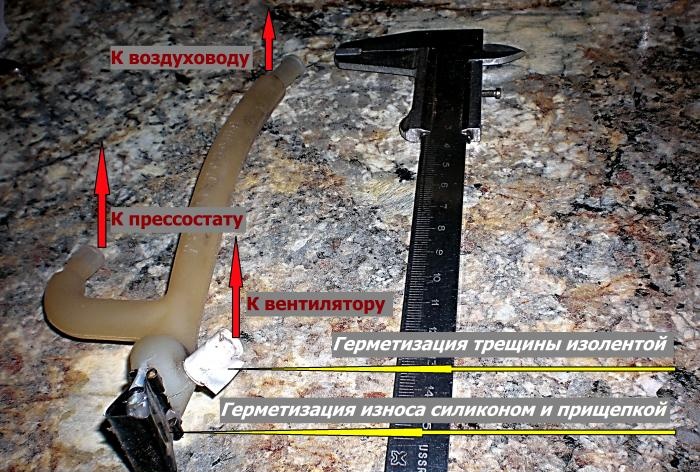

1. Condensate collector tubes. It is inspected for thermal wear and filling of the internal cavity with dirt and condensation. The tube is placed in an environment of elevated temperatures. Due to thermal radiation, the tube material loses its physical properties or becomes covered with through cracks. Also, its channels can be clogged with dirt or filled with water, which is formed due to sudden temperature changes between the environment and hot exhaust gases. If defective areas are detected, the tube must be replaced with a new one, or try to repair the worn-out product yourself.

For example, deep cracks on a cylindrical surface can be insulated with temperature-resistant material (electrical tape, aluminum tape).

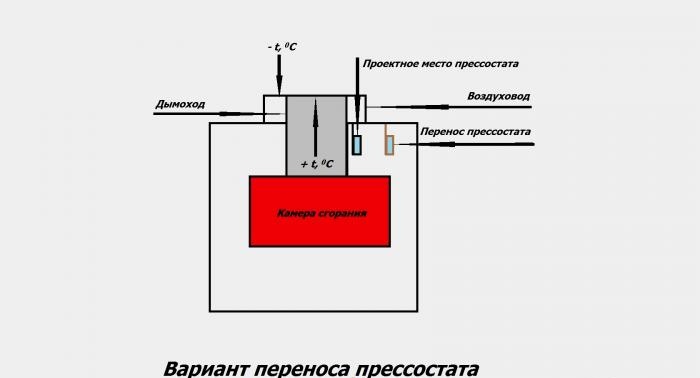

2. Internal smoke sensor chamber. When moisture gets inside the case, the microswitch contacts begin to oxidize intensively. Therefore, if condensate is constantly present in the relay, especially this process is pronounced at subzero temperatures, it is advisable to move the pressure switch of the gas boiler to another place, away from the cold wall of the supply channel.

3. Electrical contacts. Connect to pins 1 and 3 multimeter in diode test mode.

Using your mouth, create a vacuum in the chamber of smoke sensor No. 2. If the tester beeps or shows a short circuit, it means that the conductive parts of the relay are not oxidized; if one appears on the displays, therefore, they are faulty.Many models of smoke pressure switches are enclosed in a one-piece housing, so inspecting the condition of the contacts will be problematic. Since the halves of the plastic case are connected to each other by soldering, to separate it it is necessary to carefully clean off the melted areas. After opening, clean the conductive parts, inspect the membrane for defects and, if there is no significant damage, reassemble the repaired device in the reverse order. If you decide to replace it, then you need to choose a similar model.

4. Fan power. If the power of the smoke exhauster deteriorates due to a decrease in the mains voltage, severe contamination of the turbine blades or wear of the bearings, the device membrane will not be fully attracted to the microswitch. Although the relay has adjustable screws with which you can adjust the range of operation of the membrane, it is better not to touch them, since you can reset the factory settings and then set the required position for a long time. Therefore, carefully inspect the condition of the listed elements; perhaps the breakdown lies in the boiler’s smoke exhauster. You can learn about which components may be faulty in it from the article: “Diagnostics and repair of a boiler fan.”