In this article, I'm going to make a small portable miter saw powered by a 12V power supply. It will be powerful enough to cut through an inch thick piece of wood in no time.

This tool will be convenient for sawing wood and at the same time portable due to its small size. The saw is made from widely available materials, and the electric motor is taken from the drive mechanism of car wipers.

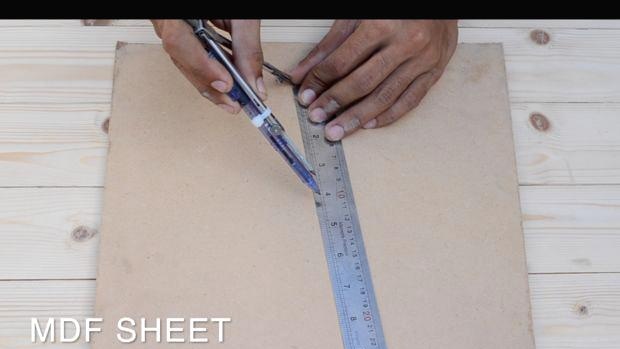

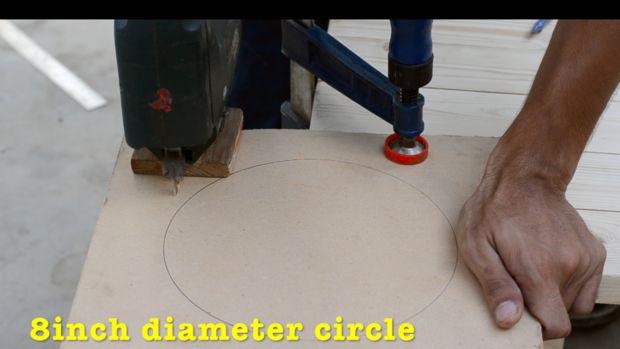

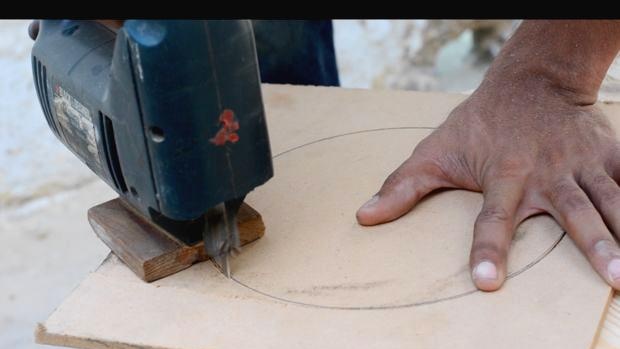

Making a saw frame

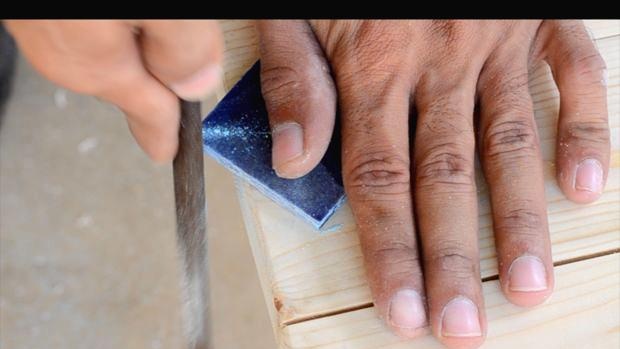

For the frame we used a 10 mm thick fiberboard sheet. First, using a jigsaw, we cut out a circle with a diameter of 20 cm and cleaned its edges.

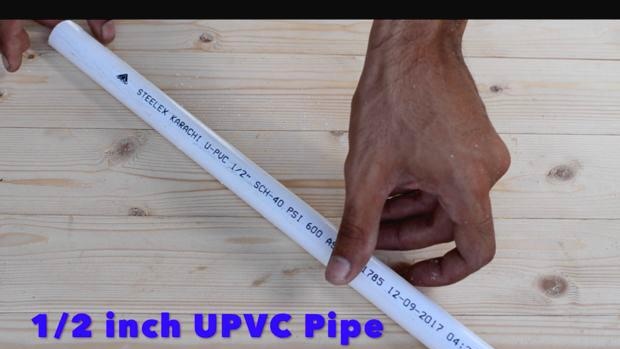

Attaching the legs

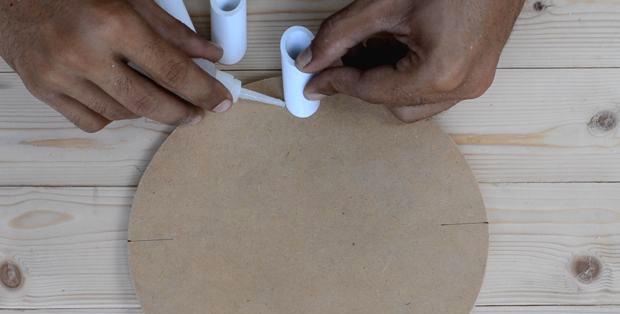

Four legs serve to raise the base above the surface. Each is made from 1/2-inch PVC pipe. For a sleeker look, each leg was cut at a 24-degree angle.

All four legs were then glued flat to the bottom of the fiberboard frame.

Preparing the base for the cutting arm

A wooden beam serves as the basis for installing the lever. It is 2.5 cm thick, 5 cm long and cut at an angle of 25 degrees. This timber was then sanded and glued to the bottom of the bed.

Cutting arm support

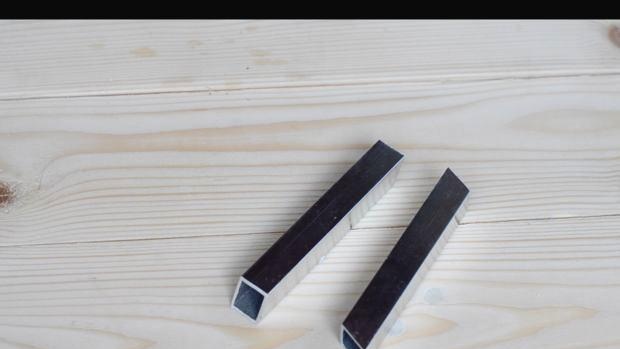

We used a 10mm thick square aluminum tube. Two pipes were cut at an angle of 25 degrees and their length was 60 mm.

They were then attached to a wooden beam using centimeter wood screws.

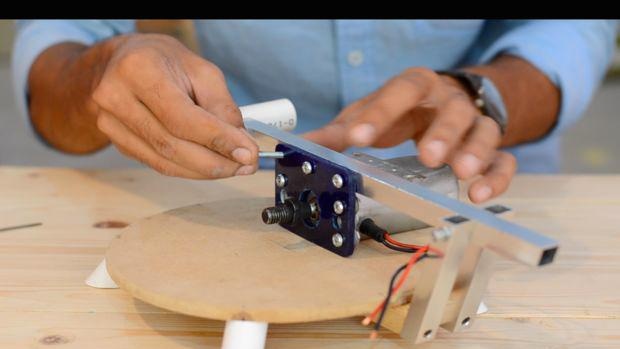

Cutting lever and handle

The handle is made from the same aluminum profile pipe. First we prepare a 25-centimeter segment. Then one of its edges is sanded and rounded inward so that the PVC pipe handle can be tightly glued to it.

Next, the cutting arm is secured between the supports using a bolt screwed through the drilled holes. The other end of the bolt is secured with two nuts.

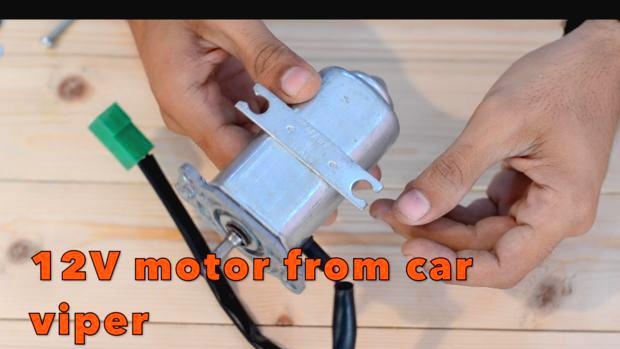

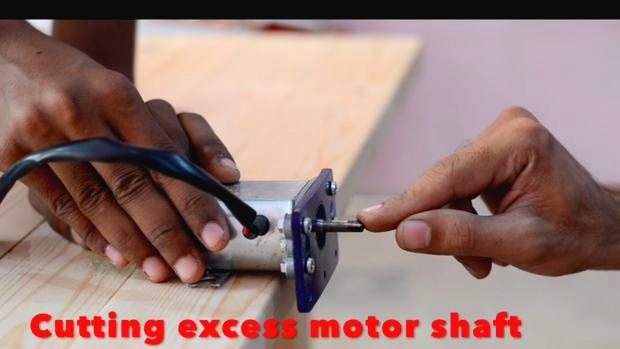

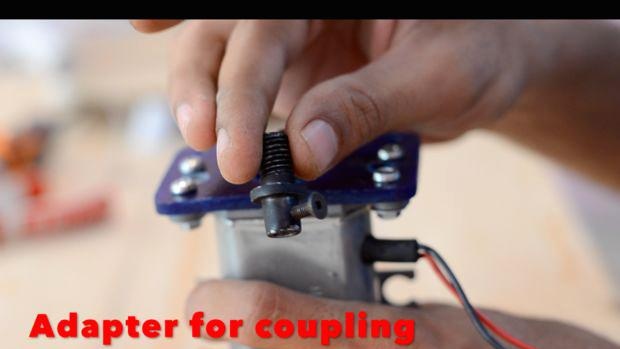

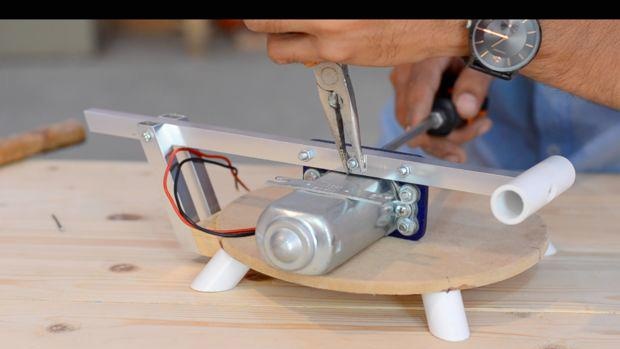

Electric motor and base for its mounting

The motor used in this project was removed from an old car's windshield wiper drive. It is powered by a 12-volt power supply.

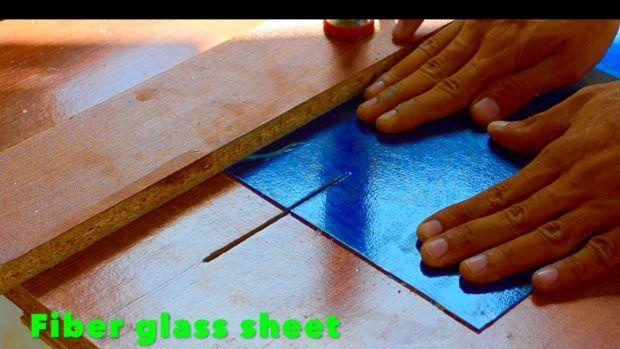

The base for installing the electric motor was made of three fiberglass plates glued together. First, the mounting holes are drilled, and then the engine is attached to the base using bolts and nuts.

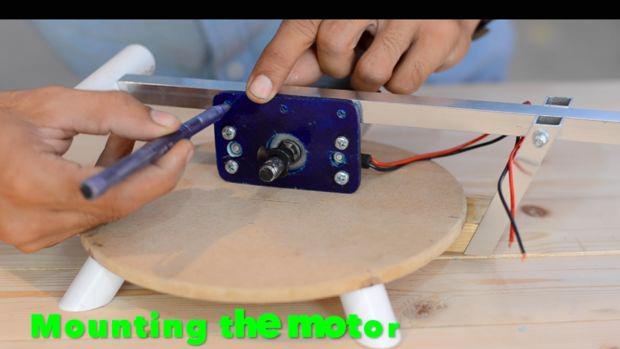

Electric motor installation

The motor is attached to the cutting arm using bolts and nuts

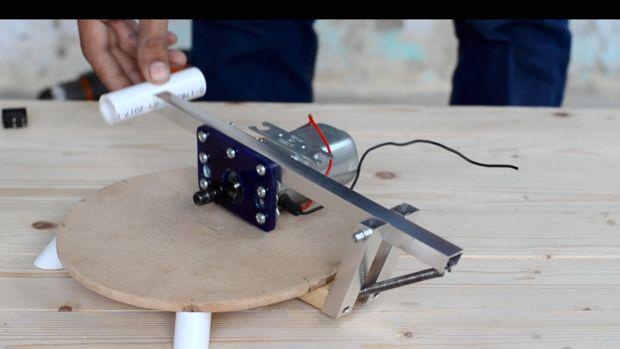

Return mechanism

For the return mechanism we used an old spring salvaged from car parts. One end of it was connected through a hole drilled in the cutting arm, and the other was secured with a bolt to its base.

This mechanism will provide a more convenient return of the lever to its previous position.

Circular Saw

I installed a 100mm disc, which is usually used in angle grinders.

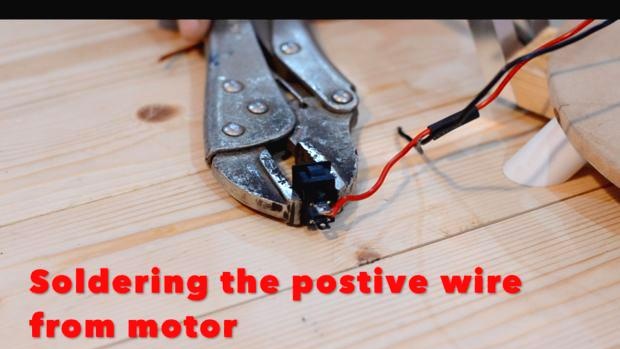

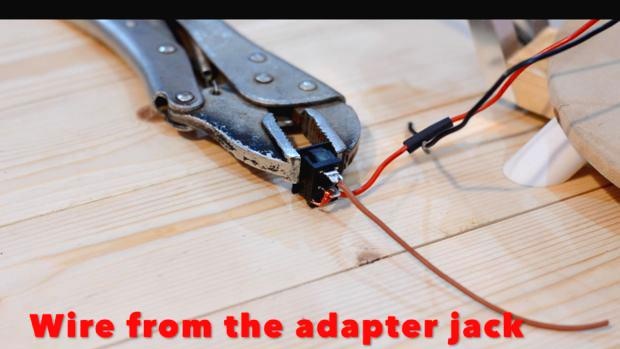

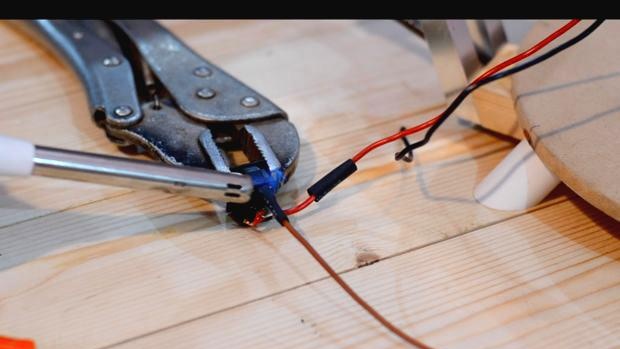

Saw wiring

The electric motor is connected to the 6 mm plug of the power supply via a switch. The saw is driven by a 12-volt power supply.

Protective cover

The protective casing is made of 100 mm PVC pipe. A section of pipe is made and half of it is securely glued to the cutting arm directly above the disc.

First, a cut is made into the frame, and then a wooden support is glued perpendicular to the cut.

The final result and work of the miter saw

The end result is impressive. The tool turned out to be compact and lightweight. It can easily cut a piece of wood that is 2.5cm thick. The best thing about this machine is that it is made from common and inexpensive materials and is driven by a 12V power supply.

Watch a video on how to make a miter saw with your own hands

Original article in English