I think many people have had to connect two stranded wires together. And most often, people simply twist the cores together. A wire connected in this way has low strength and with little force the twist can unwind and the wire break. If you have a soldering iron at hand, the twist is usually soldered and the connection strength becomes good. But what if you don’t have a soldering iron at hand? How to make high-quality twist and connect wires properly?

How to connect wires securely

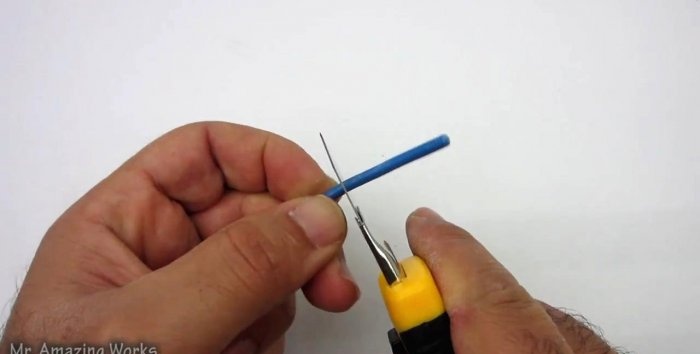

Using a utility knife or stripper, remove approximately 3 centimeters of insulation from each end of the wire.

Like this:

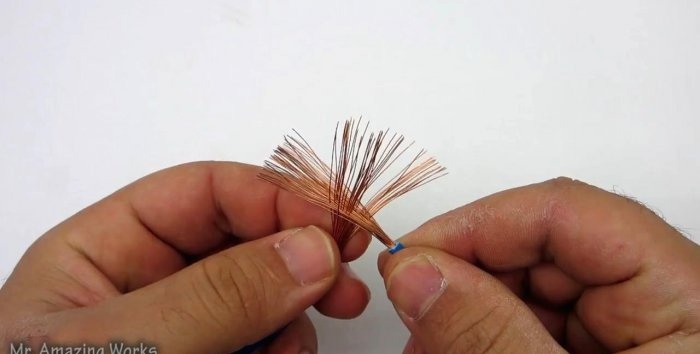

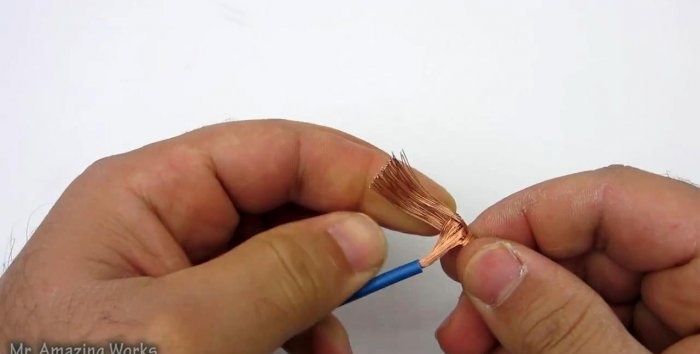

Now you need to fluff the veins into a small panicle.

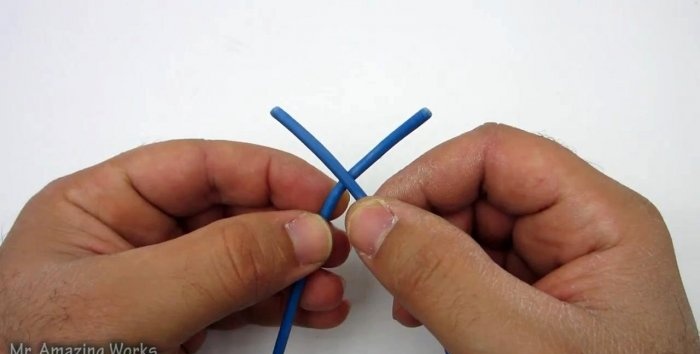

And here is the main point: these brushes need to be crossed with each other so that the wires mix together as much as possible. See photo:

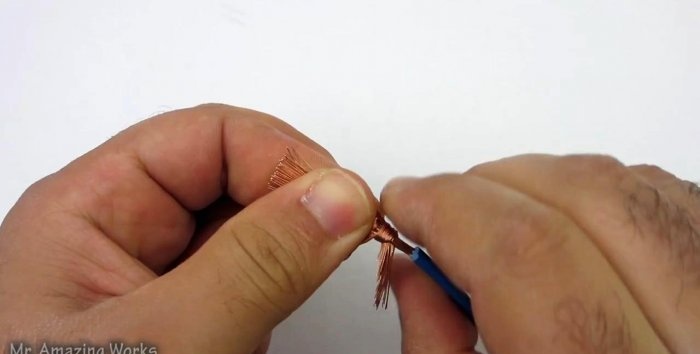

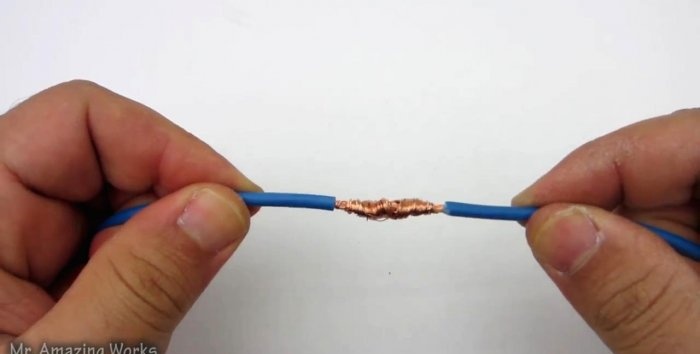

The intersection should be approximately in the middle of the exposed area. Next, after crossing the wires, we wind the right exposed area onto the left.

And left to right.

The result should be a reliable twist of wire like this.

Examination

We fix one wire on the dynamometer and pull the other.You can easily create a force of about 10 kg and the twist will not unwind, which is an indicator of excellent reliability.

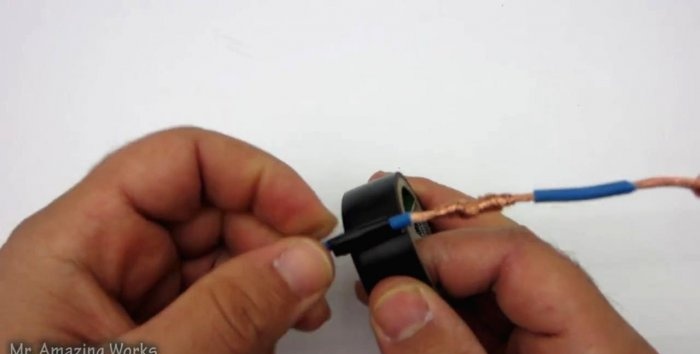

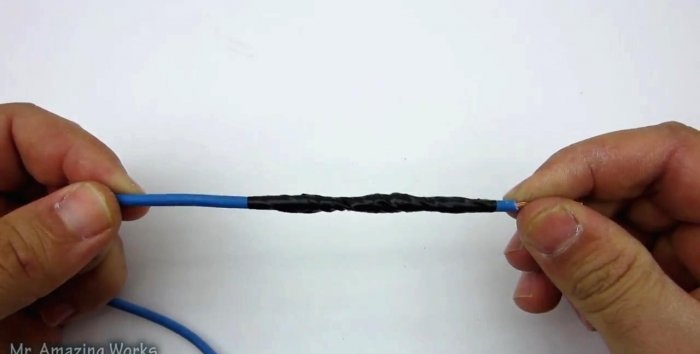

Well, then we insulate it with heat shrink or regular electrical tape.

As a result, the wire has the same reliability almost as a solid one.

Enjoy it friends! This will definitely come in handy for motorists, just as it has come in handy for me more than once.

I am sure that now you will definitely adopt this method and use it for the rest of your life, if necessary, of course.

Of course, with soldering the wire will be more reliable, but as they say, what is not there is not.

And if you know a more reliable method, write it in the comments, I’m sure everyone will be interested in learning from your experience.