The broken grinder has a gearbox that can be used to assemble various crafts. Due to the gear ratio, it makes simple mechanisms more productive. One of the successful ways to use it is to make a hand drill. This is a very useful homemade product for woodworkers and carpenters, as it allows you to drill without electricity.

Materials:

- broken grinder;

- pin M12x1.25;

- timber 100x100 mm or more;

- steel strip 20x2 mm;

- drill chuck with mounting thread M12x1.25 thread.

Hand drill manufacturing process

You need to disassemble the angle grinder and remove the rotor with gearbox. Then you need to shorten the anchor. Only part of the shaft in front of the gearbox is left.

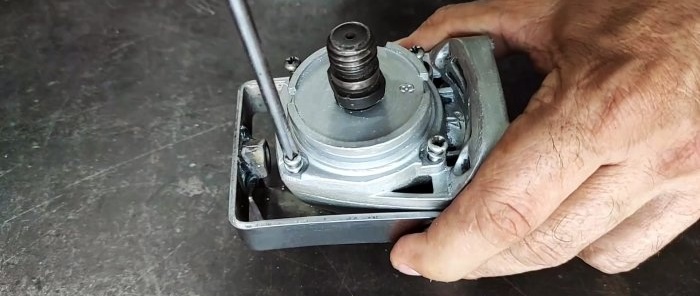

Next, you need to disassemble the gearbox and pull out the sawn shaft.

You need to lengthen it with an M12x1.25 pin in order to screw on the drill chuck in the future.

For reliability, the shaft should be drilled inside and the end of the stud should be sharpened. Then they are joined on a lathe and welded, so the alignment will be maintained. The seam is cleaned immediately.

Next we need to make the wooden body of the drill. For this, a piece of timber is used.You need to drill it in the center for the welded shaft. After this, it is cut and planed to fit the size of the gearbox.

It is required to join the housing and the gearbox, and then twist them together. To do this, the end of the first will need to be cut to the desired shape. You can also cut off excess protrusions on the gearbox.

At the next stage, a rear U-shaped bracket is made from a strip for attaching the drill stop. Holes are made in it from the edges in order to screw it to the gearbox into the standard holes for the removable handle. The bracket is also drilled in the center. An M8-M10 nut is welded to this hole to screw in the handle from the grinder. It is then screwed to the gearbox. To increase rigidity, another L-shaped blank is bent from the strip. It will need to be screwed to the third hole on the gearbox and welded with the bracket.

To rotate the drill, you will need a homemade handle. It can be made by welding an M14 nut with a piece of strip bent for convenience. A pin is welded on the edge of the resulting lever, onto which a wooden handle is mounted, then it is riveted so that it does not fly off.

The wooden parts of the drill are impregnated with oil. Then you need to return the extended shaft to the gearbox. If necessary, new bearings are installed and fresh grease is added. The shaft is also lubricated and inserted into a wooden body.

The drill chuck is screwed onto the welded pin. A handle is installed on the side of the gearbox spindle and clamped with standard grinder nuts. The standard removable angle grinder handle, which is screwed into the bracket, will serve as a stop.

As a result, we get a hand drill, the drill in the chuck of which makes 2.5-4 revolutions per turn of the handle, depending on the type of gearbox. That is, it is even better than many factory analogues, while being compact, lightweight and repairable.

Watch the video

Also see how to make a mini lathe from wood and a grinder gear - https://enn.washerhouse.com/7316-mini-tokarnyj-stanok-iz-slomannoj-bolgarki-i-dreli.html