It is difficult to make a quality hole in metal with a dull drill. At the same time, it will become very hot, which can lead to damage to the instrument. But with the help of a simple device, any adult can sharpen a drill.

Will need

- Blunt drill with a diameter of 9 mm;

- various wooden blocks;

- remnants of multilayer plywood;

- screw with nut and washers;

- brass rod;

- threaded bushing (insert);

- thread lock;

- wood oil, etc.

The manufacturing process of a drill sharpening device

From two different pieces of multilayer plywood we cut bars of equal length, but the height of the thinner one should be greater.

We glue them together so that a longitudinal difference in height is formed, and temporarily clamp them in a vice.

We mark and drill two through holes in them, different in diameter.

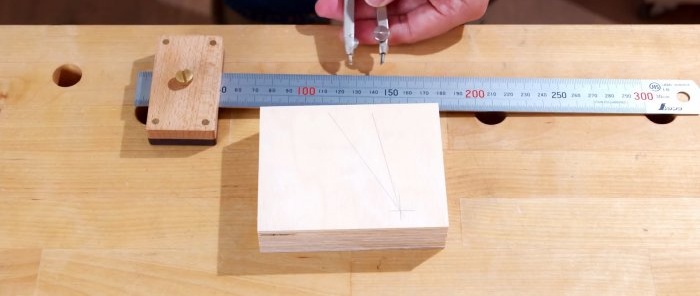

We make markings on a square of thick plywood and drill two equal holes at the points of intersection of the radii with the arc of a circle, and a third larger one in the center of the arc of the circle.

On a plywood rectangle with two holes along the edges on the longitudinal axis of symmetry next to one of them, mark a point and from it at a given angle draw a straight line to the near long side of the rectangle.

Along this straight line at an angle we glue a square with three holes vertically with the outer side so that the larger one is at the top.

We turn the structure over and secure the square to the base with two countersunk screws.

We cut off the end of a long screw according to the markings and chamfer the end.

Using this screw, washers and nut, using the holes in the bars and square, we fasten them so that the thinner bar is in the middle. We lock the nut with a thread lock.

We insert a brass rod into the smaller holes of the bars to fix them in two positions relative to the square, depending on which hole the end of the rod is inserted into.

We replace the cutting disc on a permanently mounted grinder with a sharpening disc.

We fasten the plywood structure with screws through the holes in the base to the work table of the sharpening mechanism.

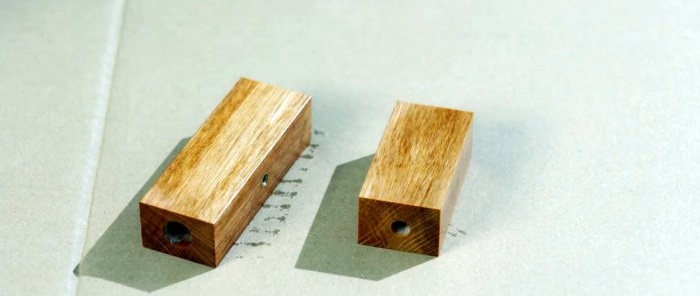

On the narrow side and end of wooden blocks of different lengths, we find the centers and drill transverse and longitudinal holes, respectively, for drills with a diameter of 9 mm and 4 mm.

We drive threaded bushings into the transverse holes, screwing screws into them in advance.

We saturate the bars with Danish wood oil.

We insert a blunt drill into the longitudinal hole of the block and fix it with the screw of the threaded sleeve.

We lay it with a drill on a block of thick plywood, pressing the side against the ledge created by a block of thin plywood.

Turn on the grinder and bring the cutting edge of the drill to the disk. As a result, the rigid arrangement of the components of the drill sharpening device creates the angle required by the tool.

To sharpen the drill at a different angle, we change the fixation of the bars in relation to the stand using a brass rod.

A comparison of the quality and time of drilling a steel strip with a sharpened and new drill showed the effectiveness of the first.