Standard factory-made knurling rollers may be excessively large for processing small workpieces. For small parts, it is better to do the knurling yourself using wheels from lighters. They are made of very hard material, so they cut into ordinary steel without any problems. Homemade knurling with narrow rollers puts less pressure on the blank from the side, thereby reducing wear on the spindle, bearings, caliper, and lead screw.

What you will need:

- Lighter wheels;

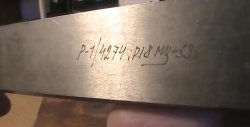

- steel square 10x10 mm;

- drill 2 mm.

Knurling process

Knurling is not a universal tool, so you won’t be able to process any part with it. It’s better to make 4 tools of different types, which can be used to roll both regular blanks from above and along the internal surfaces.

Regular and tapered knurling

One knurling is done as usual, the second with a narrowed rim to reduce the pressure on a thin workpiece during processing, the third is suitable for large internal surfaces, and the fourth cantilever knurling can be used in narrow tubes.

To make knurling, you need to prepare 4 holders. They can be obtained by shortening long cutters, or by shortening a square rod. In the holders for knurling the outer surfaces, grooves are milled at the end, slightly wider than lighter wheels.

Next, the holders are drilled for the axle to install the rollers.

One of them will need to be narrowed by grinding off the gear ring on one side.

To do this, it is put on a mandrel, which is clamped in a drill or drill. The untwisted wheel is ground down on sandpaper. The rollers are installed in holders using axles made from the shanks of broken drills.

Cantilever knurling

Cantilever knurling for small internal planes is done according to a different principle. It is necessary to sharpen the edge of the holder for the axle on which the lighter wheel will be placed.

A groove is machined in front of it for the locking ring. After this, the roller is put on and secured with a wire ring.

Side mounting mandrel

The mandrel for lateral placement of the wheel must be milled from the side to obtain 2 grooves.

Then the workpiece is drilled for the axle.

A wheel is inserted into it. The second groove is needed so that later you can squeeze out the axle and change the worn roller.

The wheels of lighters have an asymmetrical pattern, so depending on the direction of rotation of the holder, the pattern will be different. The only exception is cantilever knurling. To change the direction of the notches away from it, you need to flip the roller the other way around. This may be necessary to provide greater grip on the knurled surface when it is rotated in a clockwise or counterclockwise direction.