Not every power tool has a speed controller. But this is a necessary function that improves the quality and comfort of work. To adjust the speed mode of a non-adjustable tool, you can assemble a simple regulator with your own hands. You do not need knowledge in the radio-electronic field, since everything will be assembled on a ready-made module. This is a great option to save money and not overpay for expensive models.

What you will need:

- Mounting box;

- internal socket;

- power regulator module 2000 W - http://alii.pub/5zkesp

- wire with plug.

Speed controller assembly process

You need to cut a hole in the cover of the installation box and install a socket in it.

To keep it in place, the mounting screws on the inside of the cover are screwed into nuts with washers or a plate.

A power cord with a plug is connected to the terminals of the power regulator module. The output from it is connected by wires to the contacts of the socket.

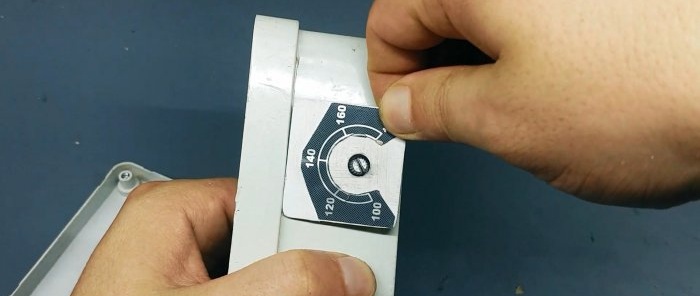

The regulator is installed in a standard hole on the side of the mounting box. The wire itself with the plug is inserted through the opposite hole.After this, the mounting box snaps into place.

Now you can adjust the parameters of the electrical network at the outlet, thereby adjusting the speed of asynchronous AC motors. These are the ones that are installed in power tools such as grinders, electric drills, jigsaws, etc.