If the jointing machine begins to “drive” defects, then the problem is most likely in the knives of its working part. Sharpening them is not an easy task and requires high qualifications. But having made a simple but reliable device, which any adult can do, a beginner can handle this delicate work.

Will need

Materials:- dull knives;

- screws;

- wooden beam.

- knife sharpening angle meter;

- drilling machine;

- electronic angle meter;

- circular saw with adjustable disc angle;

- screwdriver;

- dry" and "wet" sandpaper;

- magnets for precise installation of knives, etc.

The process of manufacturing a device for sharpening knives of a jointer

We remove the knives from the machine.

To properly sharpen the knives of a jointing machine, we will make a device. Let's start by measuring their sharpening angle, which turned out to be 38 degrees, but it could be different.

We transfer these angles to the end of the wooden square beam along two diagonals. We draw a longitudinal center line along the upper edge of the beam.

At equal distances, we mark and drill three blind holes for screws along the center line.

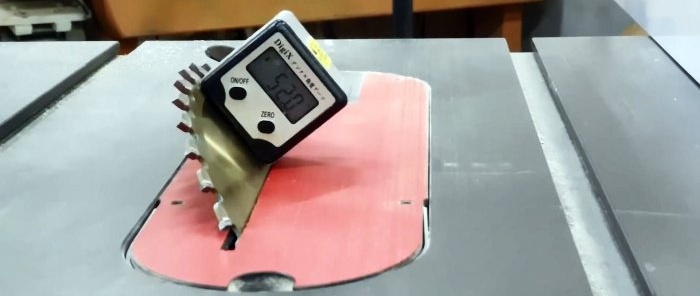

We tilt the circular saw blade to a given sharpening angle using an electronic angle meter. For us, the angle of inclination of the circular disk should be equal to 52 degrees, i.e., in addition to 90 degrees (38 + 52).

We make two cross longitudinal cuts in the beam, not reaching the center of the beam.

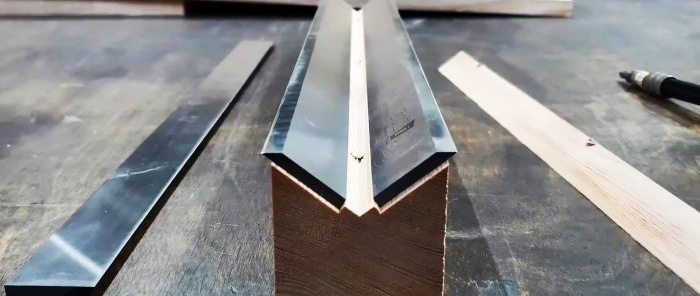

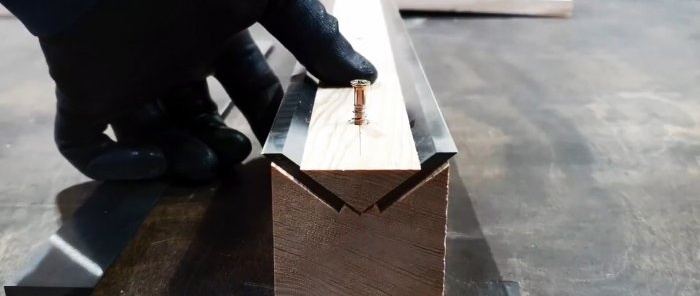

We move the side stop to the side by the thickness of the disk and again make two cross cuts to obtain a triangular strip and stops for the knives. We widen three holes in the triangular strip and insert screws into them.

We place dull knives on the inclined planes of the beam opening so that their back sides rest on the stops. We lay the triangular strip on top of the knives, tighten the screws, clamping the knives in the beam. Using a metal ruler, we check the location of the sharpening surfaces in the same plane.

The process of sharpening the knives of a jointer using a homemade device

Lay a sufficiently long strip of sandpaper on a horizontal, flat surface and secure it. We place the knives fixed in the device on sandpaper and make reciprocating movements, pressing them to the tape with the same force. Sharpening time depends on the degree of wear and the number of knives.

We straighten the back side of the knife blade using “wet” sandpaper. We check the quality of sharpening by cutting paper, cake, etc.

We install the knives in place, not forgetting to place spring plates under them. For precision installation, we use magnetic devices with appropriate settings.

We test sharpened knives after setting up the machine. We skip a piece of board with a defect that disappears without a trace. Then we pass two beams and measure their height, which turns out to be the same.The sharpened knives showed their worth.