Even experienced specialists rarely manage to achieve the service life of cutting discs declared by the manufacturer, which depends mainly on the brand and cutting method used by the master. Using high-speed photography, we will consider the features of the two main methods of cutting metal with cutting discs and choose the one that provides a longer service life.

Will need

- cutting discs of the same brand;

- Bulgarian;

- galvanized steel in the form of a channel 1.2 mm thick;

- high speed movie camera.

Any discs for angle grinders on AliExpress with a discount - http://alii.pub/61bjly

Two ways to cut metal with a cutting disc using a grinder

Most often, everyone uses two methods of cutting metal with cutting discs using a grinder:

- full plunge method (metal is cut along its entire thickness from start to finish);

- using the step-by-step cutting method (the metal is cut along its thickness in several passes with a gradual increase in the depth of cut).

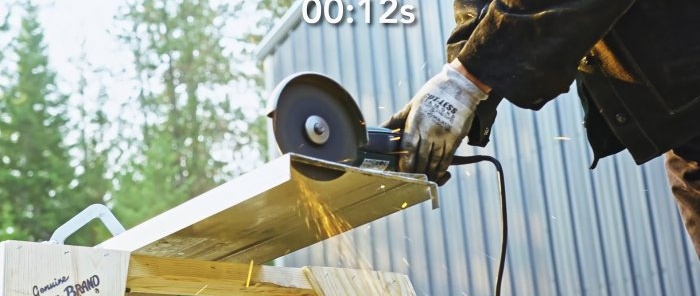

To identify a promising cutting method in terms of extending the service life of the disk, we will cut a galvanized steel sheet 1.2 mm thick, bent in the form of a channel, using the two above methods, and at the same time film the processes with a high-speed camera.

Test 1: Full plunge method

To make each cross-cut of the specified material using this method, we spent an average of 13 seconds.

We managed to complete 5 cuts and our 150 mm diameter disc was completely worn out.

To ensure reliable results, replace the worn disk with an identical new one and repeat the same operation again. This time we managed to complete 7 cuts. That is, on average there were 6 cuts (5 + 7): 2 = 6.

Test 2: Step-by-step method

This method, as expected, was slower than the first: each cut took about 32 seconds.

However, the number of cuts made by this method turned out to be disproportionately large compared to the first method - 61 cuts until a similar disk was completely worn out.

The second cutting method turned out to be noticeably slower than the first by about 2.5 times (32:13 = 2.46), but the number of cuts until the disk is completely worn out is 10 times greater (61:6 = 10.17). How can this be explained?

High speed shooting results

We point the camera lens at the place of the cut, and draw a line on the disk in the direction of the radius so that we can record the rotation of the tool. We start cutting using the full plunge method and turn on the camera.

After the operation is completed, we review the footage and it becomes clear why the disk wore out so quickly. It can be seen that the material being cut vibrates very strongly and literally destroys the edges of the disk.

Now let’s record with a high-speed camera the process of cutting metal using the step-by-step plunge method.

Watching the video after the cut is completed does not record the vibration of the material. There are also no visible particles or dust emanating from the disc, which confirms its low wear rate.

So, if there is no strict time limit, then with one disk using the step-by-step cutting method you can perform a volume of work that would require at least 10 of the same disks to complete using the full cutting method.

Any discs for angle grinders on AliExpress with a discount - http://alii.pub/61bjly

Watch the video

“Eternal” cutting discs, what is their advantage over “one-time” ones? - https://enn.washerhouse.com/8146-vechnye-otreznye-diski-v-chem-ih-preimuschestvo-v-sravnenii-s-razovymi.html