There are a great variety of options for attaching an ax head to a wooden ax handle using various devices and additional reinforcing parts and materials. But until now, the method of connecting parts of an ax in the way that our grandfathers used does not lose its relevance and can compete in results with many newfangled methods of this process. Especially if you know some little secrets.

Will need

Materials:

- old ax head;

- wooden ax;

- metal strip.

Tools: vice, sharpening machine, hand file, second ax or hammer, wood saw, grinder.

The process of attaching an ax head to a wooden ax handle in the old-fashioned way

We begin the attachment process by removing the nicks inside the eye and the edges using a file. We also smooth out the edges of the ax head, formed on it over many years of use, on a sharpening machine.

We adjust the cross-section of the ax handle at a certain length from the edge to the ax head using a sharpening machine.After such turning, we hammer the ax head onto the handle, hitting its free end with a heavy hammer, another ax or a hard surface until the ax head stops moving along the ax handle.

We leave about 1 cm of the ax from the edge of the eye and use a hand saw to cut off the part of the handle protruding from the eye, from which we will later make a wedge to strengthen the ax head on the ax.

Using the blade of another axe, hitting its butt with a hammer, we make a slot on the protruding end of the new ax in the middle in the longitudinal direction, and hammer a wooden wedge into the resulting gap until it stops. We cut off the part of the ax handle protruding from the front eye along with the wedge with a hand hacksaw.

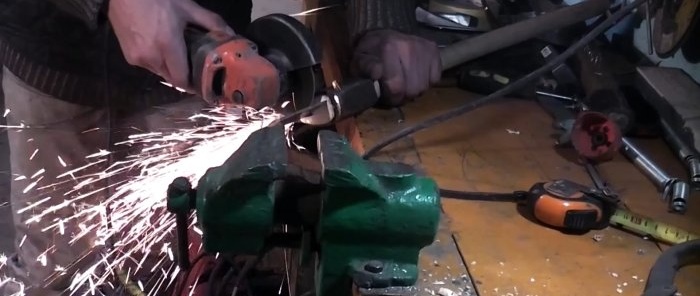

On a sharpening machine, we form a cone-shaped wedge from a steel plate of suitable thickness and width and hammer it into the ax handle obliquely, i.e., diagonally, to spread the fit of the wooden handle in the ax head along the four corners and the entire perimeter of the eye.

We cut off the upper part of the steel wedge with a grinder, leaving about 1 cm outside. We hammer this remaining part of the wedge into the ax handle flush with its end plane.

After sharpening the blade, the ax can be used without restrictions, without fear that its head will come off the handle. Using this principle, you can attach tools to wooden handles, and they will never let you down.