Such a homemade machine will make the life of craftsmen much easier, who often have to cut metal by hand with a hacksaw.

What you need to have

The main drive is an electric meat grinder. The machine itself is made from rolled metal. To make it, you need a strip approximately 2 mm thick and 1–2 cm wide, a metal pipe with a diameter of 0.5 inches, a length of approximately 50 cm, selected depending on the overall dimensions of the machine bed. The frame itself is made of profiled pipes of square and rectangular cross-section, size 30x30 mm, 10x20 mm.

For the base you need sheet iron, the dimensions depend on the dimensions of the meat grinder. The parts are assembled with M8 bolts; washers are required to ensure hinge joints. The frame is welded, so you need a welding machine.

Preparatory operations for the meat grinder screw are done on a lathe, holes are drilled on a drilling machine. The metal is cut with a grinder, and burrs are removed with it. Of course, a complete set of measuring instruments is required. After assembly, the machine is painted with metal paints.

Manufacturing technology

Disassemble the electric meat grinder and remove the feed auger from the housing.Measure the length of the drive arm that will drive the hacksaw. In our case it is approximately 10 cm, the lever is made of a 20x2 mm metal strip.

Mark the locations of the holes and drill them. You need three holes, two near the ends and one at a short distance from the first. These are mounting holes; they are later used to assemble the structure.

Using a grinder, cut the strip to size.

Place the auger in the lathe and grind off the excess metal. Remove one turn of the auger, this is necessary to prepare the stop for the vertical support and position the drive lever.

Mark on the strip the location of the support hole for the prepared auger. This parameter should be as accurate as possible.

Drill a hole at the found point. Its diameter corresponds to the diameter of the ground auger platform.

Cut off the excess length of the strip, the distance from the hole is approximately 5 mm. No special precision is required here.

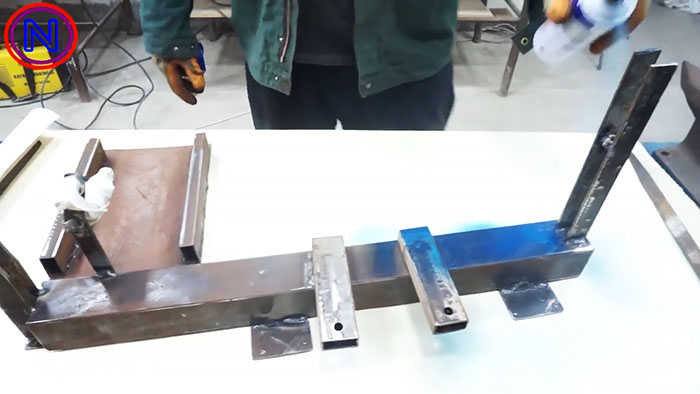

From a 10x20 mm profile pipe, make a frame body for fixing the meat grinder. Measure its length and width, place pipes around the perimeter and cut the required sizes with a grinder.

From a metal sheet, cut the base for the body of the meat grinder mounting frame. Take dimensions with the expectation that three profiled pipes will be welded around the perimeter.

Weld the workpiece to the plate, placing seams on both sides.

Clamp the auger in a vice, place two plates on the ground plate (they were made at the initial stages), and weld the short upper one to the auger. Weld a pin or bolt to the second hole of this plate. This part will drive the hacksaw. The second strip serves as a vertical support for the auger; it should rotate freely on it.Mark its length, position the auger in the meat grinder and weld the strip to the base of the frame body to secure the meat grinder. The dimensions must be as accurate as possible, the auger must rotate freely, without jamming and in a horizontal plane.

To prevent welding scale from damaging the plastic body of the meat grinder, make any protective barrier.

Make bushings, each about 3 cm long, cut the pipe into the required pieces. The internal diameter of these bushings (passage diameter) must be equal to the external diameter of the machine pipe. She will move in them, the smoother the move, the better.

Place two bushings on the drive tube and secure them together with a metal strip. The distance between the bushings is selected taking into account the length of the hacksaw blade. Make sure that the bushings are positioned strictly on the same axis, and that the strip is perpendicular to their diameters; these are important parameters. Check the smooth running of the unit.

Remove scale and check the quality of the weld. Cut another strip along the length of the welded strip. Weld it on the opposite side of the bushings.

Cut a piece of strip 7 cm long and weld it to the movable pipe. The part must be in the center; it maintains the vertical position of the hacksaw while the machine is operating. Weld the same part on the other side; between them there is a long strip connecting the two bushings.

Make a strip for attaching the hacksaw blade, its length is 8 cm. Drill a hole for the hacksaw and weld it to the frame.

Cut the second strip; its length should be shorter by about 1 cm; the sleeve of the web tensioning mechanism will be welded to it. Weld the sleeve to the strip, and then the finished part to the movable frame.

Install a hacksaw into the legs, check its position and the functionality of all elements. Weld them to long strips of movable pipe. The drive frame is made in this way and the hacksaw is fixed in it.

Tensioning the fabric is done with a pin, measure its length and cut the workpiece. Grind one end with sandpaper, making its surface flat. A hacksaw blade is attached to them.

On the flat end, drill a hole with a diameter of 3–5 mm for the hacksaw fixing bolt.

Drill a hole in the vertical support of the hacksaw (can be the one to which the tension tube is welded). It should be located in the middle of the height.

Drill a hole of the same diameter in the metal strip. This part will serve as a drive connecting rod and transmit reciprocating/forwarding movements from the meat grinder auger to the hacksaw frame.

Try on the nodes, mark the location of the second hole and drill it. Cut off the excess strip to length. All moving elements are ready, you should proceed to the frame.

Manufacturing of machine frame

Drill a hole in the end of the fixed tube.

Make two strips with holes, use the first one as a template; to increase the accuracy of measurements, clamp them with a clamp or a special device. The length of the strips should be approximately 8 cm greater than the height of the auger from the horizon.

Assemble the assembly: install strips on both sides of the tube and insert a bolt into the holes. Weld the tube supports to the meat grinder fixing frame.

Cut a piece from a 30x30 mm profiled pipe; this will be the main load-bearing element of the frame; parts for attaching the vice are welded to it. The length of the pipe is approximately 35–40 cm.

Using a grinder, carefully remove all sharp corners and burrs from the previously made movable frame for installing the hacksaw blade.

From a 10x20 mm profile pipe, cut two pieces approximately 10 cm long; they are needed to attach a vice for parts to be sawed on the machine. Drill holes for the bolts in them.

Cut two rectangles from sheet steel for fixing, approximately 5x10 cm in size, and drill four holes with a diameter of 4–5 mm in the corners.

Weld the frame parts into a single structure. Watch their position, they should all be strictly vertical and parallel, the angles between adjacent elements and nodes should only be straight.

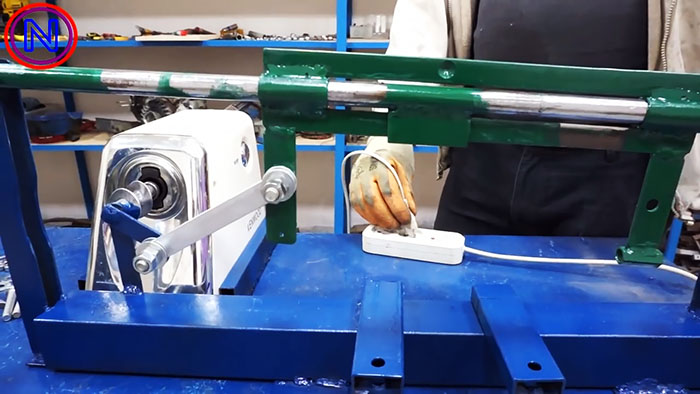

Clean the metal surfaces from rust and paint the machine. It is recommended to use blue paint for fixed parts and green for moving parts. Cover the sliding tube with paper first - the paint will create unnecessary resistance to movement.

Now all that remains is to assemble the machine components. Use bolts, washers and nuts of the appropriate sizes. Do not overtighten the hardware; they must have freedom of rotation or rolling. To prevent the nuts from unscrewing spontaneously, they should all be secured with locknuts.

First, check the functionality of the movable frame for attaching the hacksaw. Everything is normal - continue assembling the machine. Replace the hacksaw and tighten it.

Screw on the vice, insert a piece of metal into it, turn on the machine and enjoy the results of your work.

Conclusion

The more accurate the parts, the less the runout, the longer the machine lasts and the better the quality of the cut. Hence the conclusion - do not rush, maintain all dimensions with maximum accuracy.