Sometimes a master encounters difficulties in his work that cannot be solved with the help of expensive purchased tools and devices. Below are 15 life hacks that will help you get out of a difficult situation and improve your work processes.

1. How to cut a plastic pipe into rings of a given thickness

We heat the middle of the hacksaw blade for metal and bend it in half to the thickness of the washers.

Insert the ends of the blade into the slots of the wooden block and secure with a screw.

All washers obtained with such a tool will have the same thickness.

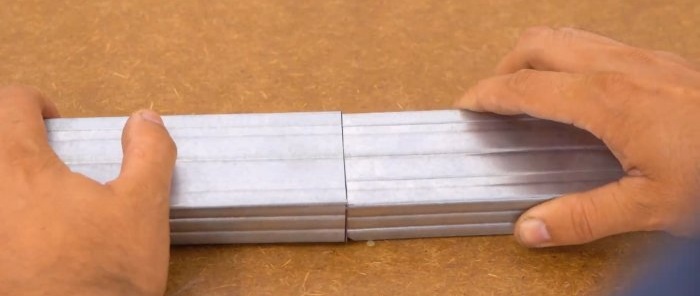

2. How to reliably join a C-shaped profile

We cut the ends of the side profile strips at 45 degrees and insert the backrest into the joining profile.

In the backs drill 3 holes and connect with rivets.

3. How to apply a ring line to a pipe

In the conical part of the plastic bottle we make transverse holes for the pipe, and in the cap for the marker. We rest the marker rod against the pipe and rotate it.

A clear ring line remains on the pipe.

4. How to remove insulation from a wire

In the track of the inner ring of the bearing we make a through slot with sharp edges. We insert a wire into it, turn the ring towards the wire and move the ring along it.

The sharp edge of the slot cuts off the insulation.

5. How to put ring lines on a jar lid

From C-shaped profile cut out a template with a side stop and strips with holes along the length, bent in relation to the stop by 90 degrees.

We apply the stop to the surface of the can and, using a marker, draw a circular line on the lid through one of the holes in the bar.

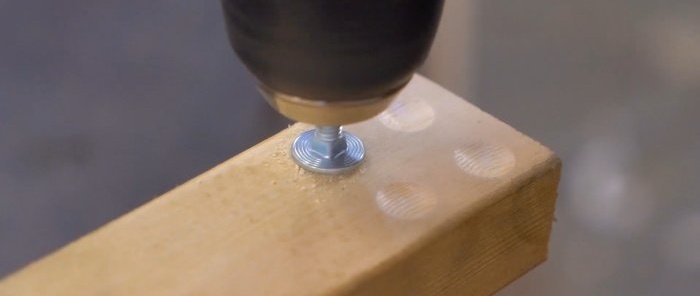

6. How to make spherical depressions in wood

We make cross-shaped slots on the spherical head of the screw.

We clamp the screw rod into the drill chuck and use the head to make indentations of a decorative or technical nature.

7. Rotating platform for working with workpieces and parts

We round the hexagonal head of the bolt to fit the bearing hole and weld in the center of the steel circle.

We fix the bolt in a vice and on a rotating platform we connect or assemble parts and workpieces that require rotation.

8. Rotary diffuser for kitchen faucet

We cut off the top of the plastic bottle, and in the cap drill several holes. We stretch half the neck of the ball onto part of the bottle, and a tight ring at the end onto the kitchen faucet.

The neck of the ball allows you to rotate the lid with holes and direct streams of water to any place in the sink.

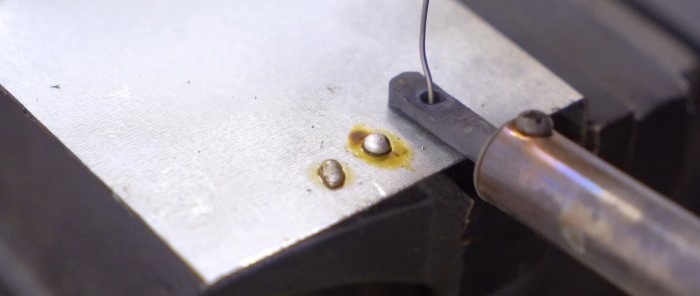

9. How to discretely distribute solder on metal

Remove the soldering iron tip, flatten the other end, drill a hole and finish it on a sharpening machine. We insert the tip with the working end into the soldering iron, secure it and heat it up.

We place the tip with the hole in the desired place, and insert the end of the soldering wire into the hole.We move the sting to another place and repeat the process.

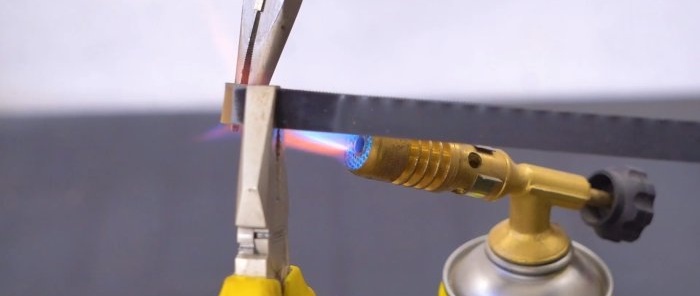

10. How to make your alligator clip more secure

Remove the sliding dielectric tubes from the clamp handles. We pass a wire with the insulation removed at the end along the groove of one part of the clamp. We draw the wire around the axis and place the bare wires in the groove of the second part of the clamp. We press the contacts of the handles to the core and to the insulation of the wire.

We return the sliding dielectric tubes to their place.

11. How to ensure tight contact of wires in the terminal block

We flatten the copper wire, bite off strips and crimp the wires until they are secured in the terminal block. Now the connection will withstand heavy loads and provide tight contact.

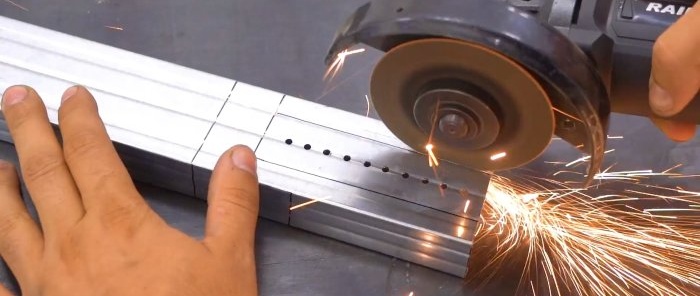

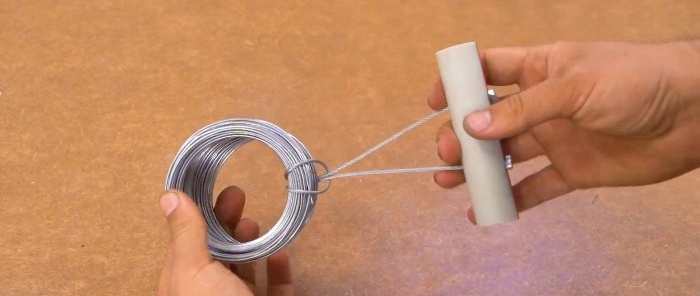

12. Means for carrying coils of wires

We drill 2 transverse holes in the plastic tube. We pass the ends of the cable through them, put on the nuts and flatten them with a hammer. We remove the ends of the cable with a grinder. We wrap the cable loop around the bay, wrap it around the ends of the tube one by one and tighten the loop.

13. Second life of the plastic pliers holder on the label

We drill a hole in the base of the plastic holder and fasten it to the wall with a screw. Now you can attach a coil of wire, a tool, an object with a suitable hole, etc. to the wall.

14. How to use the jigsaw drive for cutting

Using a sharpening machine on a replaceable blade of a stationery knife, we make the outline of the file attachment. We attach the knife to the drive and use it to cut rubber and plastic materials.

15. How to simplify the processing of parts on a sharpening machine

We drill a hole in the tool rest and secure the workpiece with a bolt and nut. The bolt prevents the part from moving, and its processing proceeds as if in automatic mode.