When cutting boards and other lumber manually at a right angle, the saw cut often deviates by a couple of degrees. You can increase its accuracy by installing a miter carriage on the saw. It is made with your own hands from available materials.

What you will need:

- Plywood 3 mm;

- thin rail;

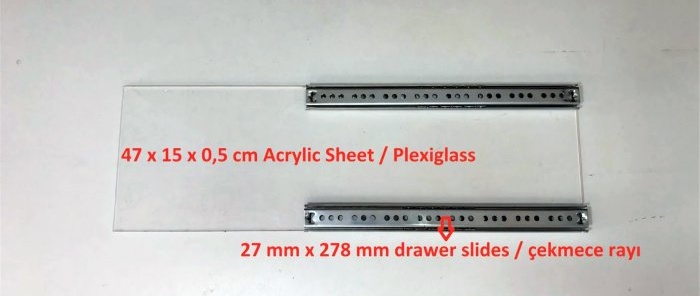

- guides for drawers – 2 pcs.;

- plexiglass 3-6 mm

- double sided tape;

- self-tapping screws;

- block 50x50 mm.

Manufacturing process of a crosscut carriage

You need to make an invoice under the main sole of the manual circular saw. To do this, plywood is cut to the standard size, with small tolerances on the larger side.

Then slats with longitudinal cuts and ends at 45° are glued onto it around the perimeter to create a frame.

Plywood is placed in it like a panel. It is necessary that these sides protrude flush with the standard sole of the circular.

On the side of the saw blade, a strip is glued onto the frame and then screwed. It will hold the false sole on the standard one.

On the reverse side, this is done by 2 self-tapping screws with washers. After installing the overhead sole, you need to turn on the circular saw and saw through it.

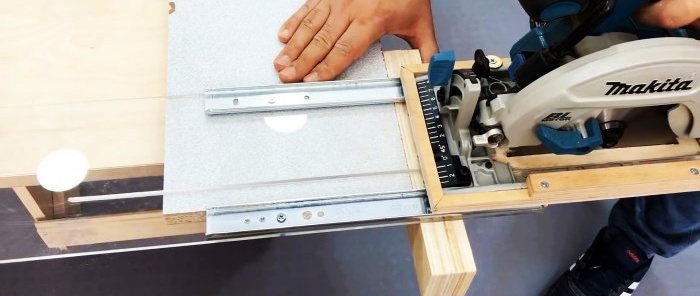

A strip of plexiglass is cut along the width of the overhead sole. The drawer guides are glued to the sides with double-sided tape. The length of the plexiglass blank should be equal to the size of the guides when opened. Next, the parts are twisted together with short self-tapping screws.

Then a removable sole is glued onto the guides. It needs to be screwed to their retractable slats.

A circular saw is installed on the resulting guide with a carriage. Then you need to turn it on and lower the disk to make a cut in the plexiglass along the entire length of the extension.

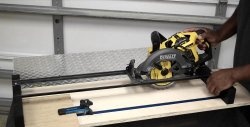

On the back side of the guide, a block stop is screwed strictly perpendicular to the saw blade. Its width must exceed the depth of the disc's reach. Then it is also sawn through.

Now the block from below is used as a parallel stop. If the side surface of the board is flat, then with such an attachment the circular saw will cut it to length strictly at a right angle.